18-CD19D5-25

35

Installer’s Guide

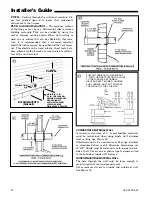

IMPORTANT:

Reinstall the propane orifices to the same depth as the

orifices supplied with the equipment.

See Table 18 for help in selecting orifices if orifice

change is required. Furnace input rate and tempera-

ture rise should be checked again after changing ori-

fices to confirm the proper rate for the altitude.

Installations above 4,000 feet may require a pressure

switch change. If required, use the BAYHALT*** Kit

(High Altitude Accessory Kit) listed in PRODUCT DATA.

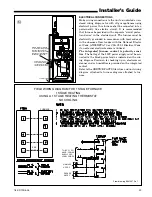

PART NUMBERS FOR REPLACEMENT ORIFICES

DRILL

SIZE

PART

NUMBER

DRILL

SIZE

PART

NUMBER

44

45

46

47

48

49

50

ORF00501

ORF00644

ORF00909

ORF00910

ORF01099

ORF00503

ORF00493

54

55

56

57

58

59

ORF00555

ORF00693

ORF00907

ORF00908

ORF01338

ORF01339

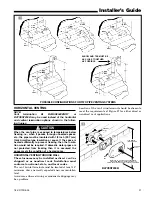

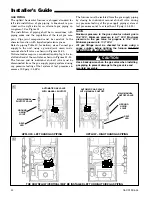

REINSTALLATION OF THE BURNER BOX COVER

Figure 55 shows the correct way to reinstall the burner

box cover if adjustment or replacement of the flame

sensor, hot surface igniter, or main burner orifices have

required removal of the cover.

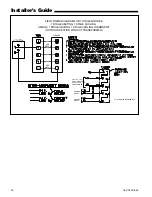

TABLE 17

Orifice

Twist Drill

Size If

Installed

At Sea

Level

ALTITUDE ABOVE SEA LEVEL

and Orifice Required At Other Elevations

2000 3000 4000 5000 6000 7000 8000 9000 10000

42

43

44

45

46

47

42

44

45

46

47

48

43

44

45

47

47

48

43

44

45

47

47

49

43

45

46

47

48

49

44

45

47

48

48

49

44

46

47

48

49

50

45

47

48

49

49

50

46

47

48

49

50

51

47

48

50

50

51

52

54

55

56

57

58

54

55

56

58

59

55

55

56

59

60

55

55

57

59

60

55

56

57

60

61

55

56

57

60

62

55

56

58

61

62

56

56

59

62

63

56

56

59

63

63

56

57

60

63

64

From National Fuel Gas Code - Table F-4

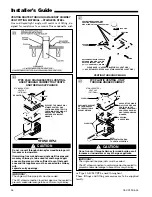

▲

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation instructions for the

venting system being placed into operation could

result in carbon monoxide poisoning or death.

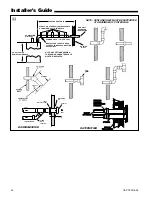

START UP AND ADJUSTMENT

PRELIMINARY INSPECTIONS

With gas and electrical power “OFF”

1. Duct connections are properly sealed

2. Filters are in place

3. Venting is properly assembled

4. Blower door is in place

Flip the switch on main gas valve within the unit to the

“

OFF

” position. Turn the external gas valve to “ON”.

Purge the air from the gas lines. After purging, Check

all gas connections for leaks with a soapy solution —

DO NOT CHECK WITH AN OPEN FLAME.

Allow 5 minutes for any gas that might have escaped to

dissipate. LP Gas being heavier than air may require

forced ventilation. Flip the switch on the gas valve in

the unit to the “ON” position.

TABLE 16

GAS FLOW IN CUBIC FEET PER HOUR

2 CUBIC FOOT DIAL

SEC. FLOW

SEC. FLOW

SEC. FLOW

SEC. FLOW

8

900

29

248

50

144

82

88

9

800

30

240

51

141

84

86

10

720

31

232

52

138

86

84

11

655

32

225

53

136

88

82

12

600

33

218

54

133

90

80

13

555

34

212

55

131

92

78

14

514

35

206

56

129

94

76

15

480

36

200

57

126

96

75

16

450

37

195

58

124

98

73

17

424

38

189

59

122

100

72

18

400

39

185

60

120

104

69

19

379

40

180

62

116

108

67

20

360

41

176

64

112

112

64

21

343

42

172

66

109

116

62

22

327

43

167

68

106

120

60

23

313

44

164

70

103

124

58

24

300

45

160

72

100

128

56

25

288

46

157

74

97

132

54

26

277

47

153

76

95

136

53

27

267

48

150

78

92

140

51

28

257

49

147

80

90

144

50

TABLE 16

T

ROTATE THE FRONT

COVER INWARD

MAKING SURE THAT

ALL SIDE FLANGES

ARE OUTSIDE OF THE

BOX.

INSERT THE TOP

FLANGE OF THE FRONT

COVER UNDER THE LIP

INSIDE THE BOX

ALL SIDE FLANGES

MUST BE OUTSIDE OF

THE BOX

ROTATE THE FRONT

COVER AS SHOWN