26

4

UNT-PRC002-GB

Technical Data

FWD

08

12

20

30

45

Power supply

(V/Ph/Hz)

230/1/50

Capacities

Cooling capacity on water (1)

(kW)

5,2

8,3

15

18,8

30,1

Heating capacity on water (2)

(kW)

6,3

11,9

18,9

20,9

38,2

Fan motor

(type)

2 x direct drive centrifugal

Fan power input (3)

(kW)

0,23

0,46

0,65

1,04

1,51

Current amps (3)

(A)

1,1

2,2

3,1

4,7

5,5

Start-up amps

(A)

3,2

5,5

9,3

14,1

16,5

Air flow

minimum

(m

3

/h)

490

980

1400

1800

2700

nominal

(m

3

/h)

820

1650

2300

3000

4500

maximum

(m

3

/h)

980

1970

2600

3600

5400

Main coil

Water entering/leaving connections

(type)

ISO R7 rotating female

(Dia)

3/4"

3/4"

1 1/2"

1 1/2"

1 1/2"

Electric heater (accessory for blower only)

Electric power supply

(V/Ph/Hz)

230/1/50

230/1/50 or 400/3/50

400/3/50

400/3/50

400/3/50

Heating capacity

(kW)

2/4

8

10

12

12

Hot water coil (accessory for blower only)

Heating capacity (4)

(kW)

6,3

12

17,4

22,4

34,5

G2 filter (filter box accessory)

Quantity

2

2

2

2

2

Dimensions ( LxWxth)

(mm)

386x221x8

486x271x8

586x321x8

586*421*8

586*621*8

G4 filter (filter box accessory)

Quantity

-

2

2

2

2

Dimensions ( LxWxth)

(mm)

-

486x264x48

586x314x48

586*414*48

586*614*48

Condensate pump (accessory)

(type)

Centrifugal

Water flow - lift height

(l/h - mm)

24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5)

(dB(A))

36/40/43

38/41/44

46/50/53

47/52/57

47/52/58

Sound power level (5)

(dB(A))

46/50/53

48/51/54

56/60/63

57/62/67

57/62/68

Unit dimensions

Width x Depth

(mm)

890 x 600

1090 x 710

1290 x 820

1290 x 970

1290 x 1090

Height

(mm)

250

300

350

450

650

Shipped unit dimensions

Width x Depth

(mm)

933 x 644

1133 x 754

1333 x 864

1333 x 1008

1333*1133

Height

(mm)

260

310

360

460

660

Weight

(kg)

32

46

61

76

118

Colour

galvanised steel

Recommended fuse size

Unit alone (aM/gI)

(A)

8/16

8/16

8/16

8/25

8/25

Unit with electric heater (gI)

(A)

16 (2kW),25 (4kW)

40 (230V),3*16 (400V)

3*20

3*25

3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

AH-SVX03C-GB

The regulating valve in the pressure side must be adjusted to the correct water quantity. The water purging volume

should be roughly equivalent to the amount of water evaporated from the system. On request we will advise you

in choosing the suitable volume. Check the correct setting with a manometer. The volume of water for sediment

flushing should be set by adjusting the flushing bleed off valve. Check the correct installation of humidifier and

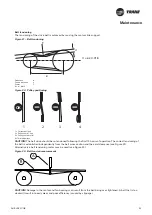

moisture separator modules. The arrow must show in the direction of the airflow (see Figure 20).

Check the tightness of the seals of the air washer and humidifier units, ie between the modules. If necessary apply

additional sealant.

Water Quality for humidifiers and air washers.

The information hereunder which refers to the water treatment is given for reference only. Water quality is of prime

concern to ensure proper operation of humidifier and air washer.

The water hardness of the fresh water has to be measured before considering any water treatement.

In accordance with the inherent degree of hardness in the water and the operational priority of the air conditioning

installation, appropriate water treatment can then be selected.

Figure 20

CAUTION! :

The use of improperly treated or untreated water in this equipment may result in scaling, erosion,

corrosion, algae or slime. The services of a qualified water treatment specialist should be engaged to determine what

treatment, if any, is required. The Trane warranty specifically excludes liability for corrosion or deterioration. Trane

assumes no responsibility for equipment damage or failure which results from the use of untreated or improperly

treated water or saline or brackish water.

Note: Honeycomb material made of cellulose may emit a certain smell during the first working hours. The is

absolutely normal and will disappear quickly.

To ensure a reasonable level of operational reliability, the quality of the supply water should be within the following

parameters (See tables 2 and 3).

Table 2

Appearance

clear, colorless and free of sediment

pH Value

7 to 8.5

Conductivity

max. 30 mS/m

Total Hardness

max. 8.1

Carbonate hardness

max. 3.5 mol/m

3

Total salt content

max. 250 g/m

3

Chloride content

0 g/m

3

Sulphate

0 g/m

3

Manganese

max. 0.01 g/m

3

Agressive Carbonic Acid

0 g/m

KMnO4 usage

max. 20 g/m

3

Table 3 –

Conversion factors for grades of hardness

Grade of hardness

° F H.

° D H.

° GB H.

France

1° F H

1

0,562

0,702

Germany

1° D H

1,78

1

1,25

Great Britain

1° GB H

1,424

0,8

1

Commissioning procedure