22

4

UNT-PRC002-GB

Technical Data

FWD

08

12

20

30

45

Power supply

(V/Ph/Hz)

230/1/50

Capacities

Cooling capacity on water (1)

(kW)

5,2

8,3

15

18,8

30,1

Heating capacity on water (2)

(kW)

6,3

11,9

18,9

20,9

38,2

Fan motor

(type)

2 x direct drive centrifugal

Fan power input (3)

(kW)

0,23

0,46

0,65

1,04

1,51

Current amps (3)

(A)

1,1

2,2

3,1

4,7

5,5

Start-up amps

(A)

3,2

5,5

9,3

14,1

16,5

Air flow

minimum

(m

3

/h)

490

980

1400

1800

2700

nominal

(m

3

/h)

820

1650

2300

3000

4500

maximum

(m

3

/h)

980

1970

2600

3600

5400

Main coil

Water entering/leaving connections

(type)

ISO R7 rotating female

(Dia)

3/4"

3/4"

1 1/2"

1 1/2"

1 1/2"

Electric heater (accessory for blower only)

Electric power supply

(V/Ph/Hz)

230/1/50

230/1/50 or 400/3/50

400/3/50

400/3/50

400/3/50

Heating capacity

(kW)

2/4

8

10

12

12

Hot water coil (accessory for blower only)

Heating capacity (4)

(kW)

6,3

12

17,4

22,4

34,5

G2 filter (filter box accessory)

Quantity

2

2

2

2

2

Dimensions ( LxWxth)

(mm)

386x221x8

486x271x8

586x321x8

586*421*8

586*621*8

G4 filter (filter box accessory)

Quantity

-

2

2

2

2

Dimensions ( LxWxth)

(mm)

-

486x264x48

586x314x48

586*414*48

586*614*48

Condensate pump (accessory)

(type)

Centrifugal

Water flow - lift height

(l/h - mm)

24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5)

(dB(A))

36/40/43

38/41/44

46/50/53

47/52/57

47/52/58

Sound power level (5)

(dB(A))

46/50/53

48/51/54

56/60/63

57/62/67

57/62/68

Unit dimensions

Width x Depth

(mm)

890 x 600

1090 x 710

1290 x 820

1290 x 970

1290 x 1090

Height

(mm)

250

300

350

450

650

Shipped unit dimensions

Width x Depth

(mm)

933 x 644

1133 x 754

1333 x 864

1333 x 1008

1333*1133

Height

(mm)

260

310

360

460

660

Weight

(kg)

32

46

61

76

118

Colour

galvanised steel

Recommended fuse size

Unit alone (aM/gI)

(A)

8/16

8/16

8/16

8/25

8/25

Unit with electric heater (gI)

(A)

16 (2kW),25 (4kW)

40 (230V),3*16 (400V)

3*20

3*25

3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

AH-SVX03C-GB

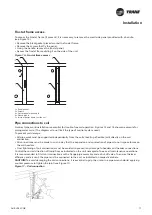

Figure 18

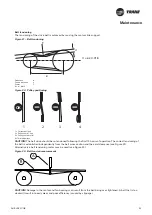

Figure 19

Pre-start checklist

Initially the complete unit and all components should be thoroughly cleaned and all dust and other deposits

completely removed.

The unit must be maintained in a clean condition.

Prior to dispatch, each unit is thoroughly checked. Nevertheless, as part of the commissioning procedure, it is

imperative to recheck certain items as listed below.

Check that there are no foreign bodies in the unit or in the duct system and that air inlet sand outlets are not

blocked.

Some of the settings on the unit may have changed during transportation and installation process.

Make sure all bolts and screws are tightened, especially moving parts such as fan pulleys, bearings etc.

Make sure electrical connections are tightened.

For units with variable air volume devices, check that dampers are fully open.

Make sure that the dampers move freely in their correct positions and that they operate correctly.

If the unit is provided with a cross flow heat recovery exchanger, it is designed to resist at the nominal

differential pressure indicated on the technical sheet, so all dampers and interception devices must be opened.

This action should be interlocked to the control system.

Fan motor

Check that the fan revolves freely by turning the impeller manually and verify that no foreign bodies are lodged

in the fan scroll.

Remove the locking block under the motor-fan base frame.

Check that the fixing screws on the belt pulleys are tight (see Figures 18 and 19).

Check the fan belt tension and pulleys alignment. Realign and retighten if necessary (See Maintenance section).

Make sure that the dampers move freely and that any transport packing has been removed.

Check the motor connections and make sure that the correct voltage supply is being used. Verify the lubrication

of fan and motor bearings (See Maintenance section and follow the motor manufacturer's recommendations).

Bearings could be pre-lubricated. Start-up may be noisy until grease is evenly distributed. Please refer to the

individual supplier's installation, operation, and maintenance manuals for additional information.

If adjustable pulleys have been fitted, ensure they are positioned in the correct ratio. The setting is done at the

factory and should not require further adjustment. If adjustment must be made, refer to the section about pulleys

in this manual.

Fan must not work with interception device closed, like dampers, in order to avoid permanent deformation of the

structure. Dampers must be open during fan operation. Trane cannot be held responsible of structural damages

due to that.

Commissioning procedure