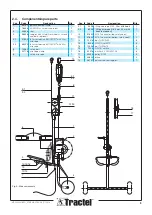

7

11

1

A

9

1

21

7

A

D

E

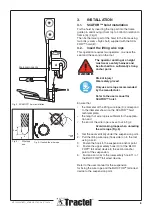

Insert the lifting wire rope (Fig. 6)

Pass the lifting wire rope over the 2 nylon pulleys of

1.

the steel frame.

Manually insert the end of the wire rope into the

2.

central hole on the top part of the SCAFOR

TM

hoist

housing.

Manually push the wire rope through the hoist

3.

using the yellow handle (D) to open the jaws.

Turn the right-hand handle (21) clockwise until the

4.

wire rope emerges from the bottom. Where neces-

sary, push the wire rope to ease it through.

Manually guide the end of the wire rope to ensure

5.

that it passes through the wire rope guide (guide

tube) (E).

Run the wire rope through the hoist until it is taut.

6.

Fix the wire rope safety clamp (7) to the carrying

7.

wire rope (Fig. 6) at about 200 mm from the guide

tube. Tighten the two locknuts.

Wind the unused length of wire rope on a reel.

8.

3.3. Fasten the safety wire rope

Refer to the user manual for the

BLOCFOR™ fall arrest device.

The operator on the ground must slowly pull the

1.

rope (A) attached to the hook of the fall arrest

device BLOCFOR

TM

until the hook reaches him.

(Fig.7)

Warning: never let go of the rope (A) during this

operation.

Hold on to the safety wire rope firmly at the collar.

2.

Do not let go of the wire rope.

Fix the connector (safety hook) (11) to the steel

3.

frame (1) without letting go of the wire rope.

Tightly screw the safety hook collet without locking

4.

it.

Let go of the safety wire rope, remove rope (A) and

5.

store it away.

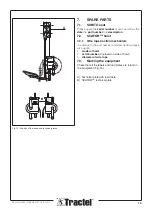

hook

collet

Handle/securing

device with connector

Data plate

Buffer

Hook for connector

Handling handle

Insert the lifting wire rope

Fig. 6 -

Fasten the safety wire rope

Fig. 7 -

BLOCFOR™

Fig. 8 -

- MC1452-SUBITO_6FR-EN-D-IT-ES-NL 0

7

/201

8