12

d

6.

MAINTENANCE

6.1.

Yearly check

Every installation must be checked annually by the

manufacturer or by an approved repairer.

The SCAFOR™ hoist must be checked annually.

The SCAFOR™ hoist must be overhauled annually, or

at the very least, in compliance with the rules and re-

gulations of the country in which it is used (in France :

overhaul required every 3 months per decree dated

June 9, 1993, article 23).

6.2. Regular maintenance

The following simple maintenance operations may

be carried out by unqualified personnel.

Refer to the fall arrest equipment operating and main-

tenance manuals for detailed control and maintenance

operations of:

– fall arrest device with winder, series BLOCFOR

– connectors, series M

6.2.1. Lubrication of wire ropes

The suspension and secondary wire ropes must be

regularly lubricated using an oiled cloth. Use semi-fluid

SAE 20/30.

Never use oil or grease containing

molybdenum disulphide or graphite

additives

6.2.2. Replacing the wire ropes

Only wire ropes approved by the TRACTEL Group

ensure the correct operation of the hoists in com-

plete safety.

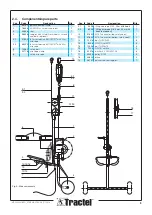

SCAFOR

TM

wire rope is defined by:

itsTRACTEL

•

®

S identification = a red strand with

the TRACTEL

®

logo on the ferrule

its diameter = 6.5 mm

•

its length

•

its end fittings:

•

- a hook with safety catch and

- a fused and tapered end (Fig. 4)

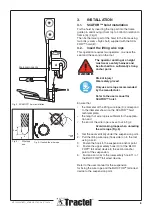

Danger

Examples of damaged wire rope to be replaced

Fig. 13 -

its construction.

•

If any of the faults below is detected the wire rope must

be replaced:

more than 12 broken wires over a 24 cm length

•

damaged or deformed wire rope

•

corrosion

•

heat damage

•

reduction of diameter of the suspension wire rope:

•

minimum diameter = 5.9 mm.

Wire rope to be measured as shown in fig. 14.

6.2.3. Checking fall arrest device linked to the

seat support

Refer to the user manual for the

BLOCFOR™ fall arrest device.

a. Checking winder

Checking appearance:

Prohibit the use of all equipement showing signs of

•

strain, oxidation, etc.

Do not put foreign products (oil, solvent, etc.) into

•

the equipment.

Unwind the whole wire rope and check it for signs

•

of damage (strain, broken wires, etc.), wind the

wire rope by guiding it.

Do not let go of the wire rope.

Clean and grease the wire rope with an oil-impre-

•

gnated cloth.

Checking the grip:

Apply a sharp pull to the end of the wire rope by

•

hand.

The winder must block the wire rope as soon as

•

the release speed is reached.

Guide the wire rope to its starting position by let-

•

ting it re-wind itself in the housing.

Do not let go of the wire rope.

Check that the winder anchor is positioned above

•

the user and perpendicularly to the working posi-

tion.

b. Environment check

Check that the wire rope cannot touch a sharp

•

edge.

Check that the fall arrest wire rope cannot touch

•

and/or rub against an electrical cable or conductor

or any fluid-conveying equipment.

Check that the wire rope is not exposed to a tem-

•

perature exceeding 100°C and to mechanical or

chemical strains.

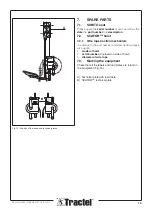

Correct measuring of wire rope diameter.

Fig. 14 -

Warning

- MC1452-SUBITO_6FR-EN-D-IT-ES-NL 0

7

/201

8