EM-42

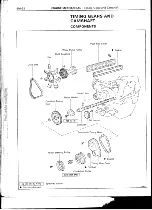

ENGINE MECHANICAL - Cylinder Block

(f)

Place the crankshaft on the cylinder block.

(g)

Lay a strip of Plastigage across each journal.

(h)

Install the main caps.

Torque:

19 mm bolt head

1,375 kg-cm (99 ft-lb, 135 N•m)

17 mm bolt head

1,175 kg-cm (85 ft-lb, 115 N•m)

HINT: Do not turn the crankshaft.

(i)

Remove the main bearing caps.

(j)

Measure the Plastigage at its widest point.

Standard oil clearance:

STD size

0.020 - 0.044 mm

(0.0008 - 0.0017 in.)

U/S 0.25 and 0.50

0.021 - 0.067 mm

(0.0008 - 0.0026 in.)

Maximum oil clearance: 0.10 mm (0.0039 in.)

HINT: If replacing the cylinder block subassembly the

bearing standard clearance will be:

0.004 — 0.060 mm (0.002 — 0.0024 in.)

If the oil clearance is greater than maximum, replace the

bearings. If necessary, grind or replace the crankshaft.

HINT: If replacing a standard size bearing with a stan-

dard oil clearance, replace with one having the same

number. If the number of the bearing cannot be deter-

mined, select a bearing from the table below according to

the numbers imprinted on the cylinder block and

crankshaft.

There are five sizes of standard bearings, marked T1, T2,

T3, T4 and T5.

Number marked

Crankshaft

3

4

5

Cylinder block

6

7

8

6

7

8

6

7

8

Bearing

T3

T4

T5

T2

T3

T4

T1

T2

T3

Example: Crankshaft "5", Cylinder Block "7"

= Bearing "T2"