FI2502

Throttle Lever

U

C^

No Clearance 0

Throttle Stop

Screw

F12355

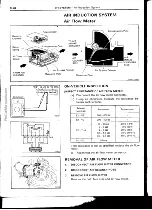

EFI SYSTEM — Air Induction System

FI-65

VC

1ti

VTA

IIJ

^^

^j_l—EDL

^

\

E2

IDL

VIA

VC

F10507

Clearance between

lever and stop screw

Between terminals

Resistance

0mm(0in.)

VTA—E2

0.3-6.3kQ

0.77 mm (0.0303 in.)

I DL — E2

Less than 2.3 kQ

1.09 mm (0.0429 in.)

IDL— E2

Infinity

Throttle valve fully

ope

opened position

VTA—E2

3.5-10.3kQ

VC — E2

4.25 — 8.25 kQ

(d) Reconnect the sensor connector.

REMOVAL OF THROTTLE BODY

1.

DRAIN ENGINE COOLANT

2.

DISCONNECT ACCELERATOR AND THROTTLE

CABLES

3.

DISCONNECT AIR CLEANER HOSE

4.

DISCONNECT THROTTLE POSITION SENSOR

CONNECTOR

5.

DISCONNECT WATER HOSES

6.

DISCONNECT VACUUM HOSES

7.

REMOVE THROTTLE BODY

Remove the three bolts, nut, throttle body and gasket

I NSPECTION OF THROTTLE BODY

1. CLEAN THROTTLE BODY

(a)

Using a soft brush and carburetor cleaner, clean the

cast parts.

(b)

Using compressed air, clean all the passages and

apertures.

NOTICE: To prevent deterioration, do not clean the

throttle position sensor.

2. INSPECT THROTTLE VALVE

Check that there is no clearance between the throttle

stop screw and throttle lever when the throttle valve is

fully closed.