a

EFI SYSTEM — Troubleshooting

FI-11

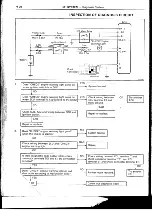

OK CONTINUED FROM PAGE FI-10

CHECK SPARK PLUGS

Standard: 0.8 mm (0.031 in.)

HINT: Check compression pressure and

valve clearance if necessary.

1. Spark plugs

NO

2. Compression pressure

Minimum: 8.0 kg/cm2

(114 psi, 785 kPa)

at 200 rpm

3. Valve clearance (Hot)

Standard: IN 0.20 mm (0.008 in.)

EX 0.35 mm (0.014 in.)

1. Injector(s) — shorted or leaking

BAD

2. Injector wiring — short circuited

All

3. Cold start injector — leakage

Plugs

(See page FI-50)

WET

4. Cold start injector time switch

(See page FI-72)

OK

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel line — Leakage — deformation

1. Fuel in tank

BAD

2. Fuse

2. Fuel pressure in fuel line

3. Fuel pump (See page FI-44)

(1) Connect ter B and FP of

4. Fuel filter

the check connector.

5. Fuel pressure regulator (See page FI-53)

(2) Fuel pressure at fuel hose of fuel

filter can be felt. (See page FI-45)

OK

CHECK FUEL PUMP SWITCH IN AIR

Air flow meter (See page FI-62)

FLOW METER

BAD

Check continuity between terminals FC

and El while measuring plate of air flow

meter is open.

OK

CHECK IGNITION TIMING

1. Connect terminals TE1 and El of the

NO

check connector.

2. Check ignition timing.

Standard: 7°BTDC A

idle

( w/ connected TE1 and El)

OK

CHECK EFI ELECTRONIC CIRCUIT

USING VOLT/OHMMETER

BAD

(See page FI-27)

Ignition timing — Adjust (See page EM-1 1)

1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay (See

3. Air flow meter (See pagE

4. Water temp. sensor (See

5. Air temp. sensor (See pa

6. Injection signal circuit

(1) Injector wiring

(2) ECU (See page FI-7'