ATTACH THE FUEL LINES

❍

5. Cut two pieces of fuel tubing (not included) 5" (127mm) in

length. Attach these to the plastic tubes that are on the fuel tank. You

may need to hold the tank in position with one hand while installing

the tubes with the other.

Note: It may be necessary to attach the carburetor to your particular

engine. Follow the manufacturer’s instructions for this procedure.

INSTALL THE THROTTLE PUSHROD

❍

1. Attach the “Z” bend into the inside hole of the carburetor

control arm. Make sure that the “Z” bend does not interfere with any

parts of the engine.

The engine in your airplane is mounted slightly different from that of

most R/C aircraft. This is done to allow the use of many different

types of engines. It also allows a “no-drill” approach to ease the

installation.

Read through the procedure and understand all the steps

before actually performing them.

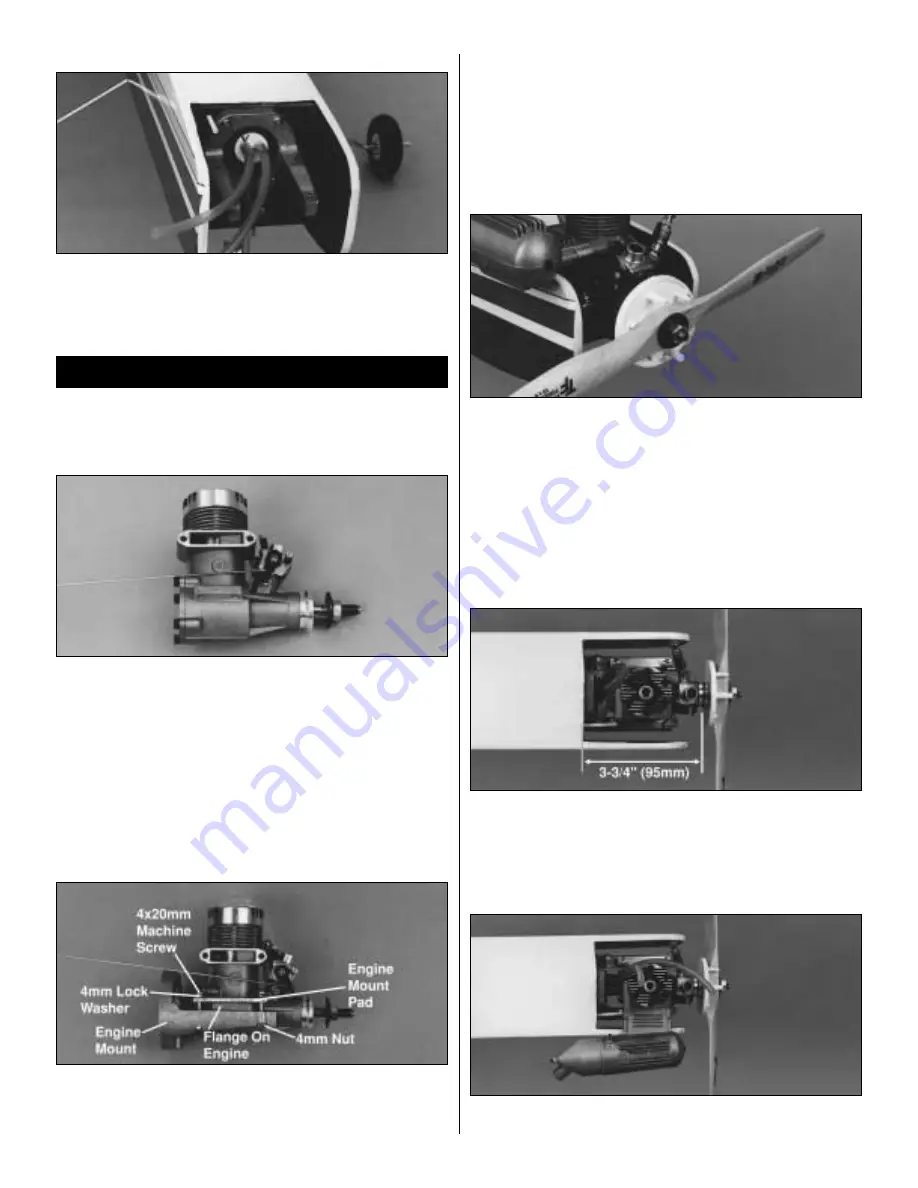

MOUNTING THE ENGINE

Note: The engine and mount have been removed from the aircraft for

photography. Do not remove the engine mount from the aircraft.

❍

2. The engine is “sandwiched” between the engine mount and the

engine mount pads. Slide the throttle pushrod into the pushrod tube

in the fuselage and rest the engine on the mount. Slide a 4mm lock

washer onto a 4 x 20mm machine screw. Repeat this process for the

remaining screws and washers. Pass the screws through the engine

mount pads. The screws then go through the mount, passing in front

of and behind the engine mounting flange. The pads will be resting

on the top of the engine’s mounting flanges. The 4mm nuts are then

placed into the recesses on the bottom of the engine mount. Start the

screws, but do not tighten them at this time. We still need to align

the engine!

ATTACH THE PROPELLER TO THE ENGINE

❍

3. Install the spinner backplate, propeller, propeller washer and

the propeller nut onto the engine. Turn the propeller counterclockwise

until it is against the smallest pins on the backplate. Keep the propeller

horizontal when the engine is against its compression (the point at

which you feel resistance when you turn the crankshaft counterclockwise).

This is a good habit to get into when installing propellers onto model

airplanes. If the engine quits during flight, the propeller will stop

horizontally, therefore reducing the chance of propeller breakage if

you are forced to land on rough terrain. Use an adjustable wrench

(not a pliers) to securely tighten the propeller nut.

ALIGNING THE ENGINE

❍

4. Measure the distance from the spinner backplate to the firewall.

It should be 3-3/4" (95mm) on both sides. Adjust the engine if needed

and tighten the screws evenly to secure the engine to the mount.

INSTALL THE MUFFLER

❍

5. Following the engine manufacturer‘s instructions, install the

muffler to the engine.

ENGINE INSTALLATION

12