All repair qualifying under this limited warranty must be performed by a sewice

dealer authorized by us

.

In the event that any emission-related part is found to be

defective during the warranty period

,

you shall notify our CORPORATION Product

Support Department

3

.

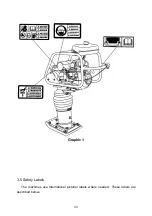

SAFETY lNFORMATlON

This manual contains DANGER, WARNING

,

CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service

.

This is the safety alert symbol

.

It is used to alert you to potential personal

injury hazards

.

Obey all safety messages that follow this symbol to avoid

possible injury or death

.

DANGER

indicates a hazardous situation which

,

if not avoided

,

will result

in death or serious injury

.

WARNING

indicates a hazardous situation which

,

if not avoided

,

could

result in death or serious injury

.

CAUTION

indicates a hazardous situation which

,

if not avoided

,

could

result in minor or moderate injury

.

CAUTION

:

Used without the safety alert symbol

,

CAUTION indicates a potentially

hazardous situation which

,

if not avoided

,

may result in property damage

.

Note

:

Contains additional information important to a procedure

.

3.1 Operating Safety

Familiarity and proper training are required for the safe operation of

equipment. Equipment operated improperly or by untrained personnel can

be dangerous. Read the operating instructions contained in both this

manual and the engine manual and familiarize yourself with the location

and proper use of all controls. Inexperienced operators should receive

instruction from someone familiar with the equipment before being allowed

to operate the machine

.

3.1.1

NEVER

operate this machine in applications for which it is not intended

.

3.1.2

NEVER

allow anyone to operate this equipment without proper training. People

operating this equipment must be familiar with the risks and hazards

associated with it.

3.1.3

NEVER

touch the engine or muffler while the engine is on or immediately

7

Содержание TP880-1

Страница 2: ...GASOLINE TAMPING RAMMER TP880 1 TP880 2 TP880 3...

Страница 28: ...TP880 1 TP880 2 TP880 3 Exploding view 27...

Страница 30: ...TP880 1 TP880 2 TP880 3 Crank case assembly 29...

Страница 32: ...TP880 1 TP880 2 TP880 3 Cylinder assembly 31...

Страница 34: ...T1217 V04 MADE IN CHINA www totaltools cn TOTAL TOOLS CO LIMITED GASOLINE TAMPING RAMMER...