for oil quantity and type

.

●

if the warning light stays on continuously

,

the engine will start and continue to run but

the low oil shutoff switch is not functioning properly

.

Check the switch for proper wire

connections. If the light continues to stay on

,

replace the switch

.

●

if the warning light does not flash quickly once

,

and the engine starts and continues to

run

,

the low oil shutoff switch is not functioning properly

.

Check the switch for proper

wire connections and grounding

.

If the light still does not flash when starting the

machine

,

replace the switch

.

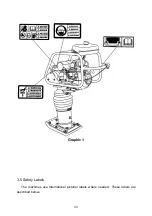

5.7 Proper Operation

See Graphic 3

Keep vibratory rammer clean and dry

.

Avoid no-load strokes

.

Never allow the rammer

to run full throttle when forcing away materiaI or when lifting the equipment

.

For optimal control, performance

,

and minimaI hand/arm vibration, grasp handle as

shown

.

Hand/arm vibration (HAV) has been optimized for this positioning

.

Reported

HAV levels are measured at position A just in front of the hand position shown in

conformance with EN 1033 and ISO 5349.

CAUTION

:

To prevent damage to the rammer

,

do not allow the rammer to run on its side

.

If the rammer should tip on its side

,

place the rammer in the position shown

,

then shut

off the engine by turning engine switch to "OFF"

.

Graphic 3

5.8 Proper Compaction

See Graphic 4

5.8.1 Run rammer at the full throttle position(a2)for maximum performance

.

5.8.2 Guide rammer with its handle

.

Allow machine to pull itself forward

.

DO NOT try

to over-power the machine

.

5.8.3 For best compaction

,

the shoe must hit the ground flat (b)

,

not on its toe or heel.

This will save on excessive shoe wear

.

19

Содержание TP880-1

Страница 2: ...GASOLINE TAMPING RAMMER TP880 1 TP880 2 TP880 3...

Страница 28: ...TP880 1 TP880 2 TP880 3 Exploding view 27...

Страница 30: ...TP880 1 TP880 2 TP880 3 Crank case assembly 29...

Страница 32: ...TP880 1 TP880 2 TP880 3 Cylinder assembly 31...

Страница 34: ...T1217 V04 MADE IN CHINA www totaltools cn TOTAL TOOLS CO LIMITED GASOLINE TAMPING RAMMER...