– 18 –

Outdoor Unit

Installation Manual

■

Refrigerant Recovery

When recovering the refrigerant in situations such as when relocating an Hydro Unit or Outdoor Unit, the recovery

operation can be performed by operating the SW01 and SW02 switches on the P.C. board of the Outdoor Unit.

A cover for the electric parts has been installed in order to provide protection from electric shocks while work is

being performed. Operate the service switches and check the LED displays with this electric parts cover in place.

Do not remove this cover while the power is still on.

DANGER

The entire P.C. board of this Air to Water Heat Pump system is a high-voltage area.

When operating the service switches with the power of the system left on, wear electrically insulated gloves.

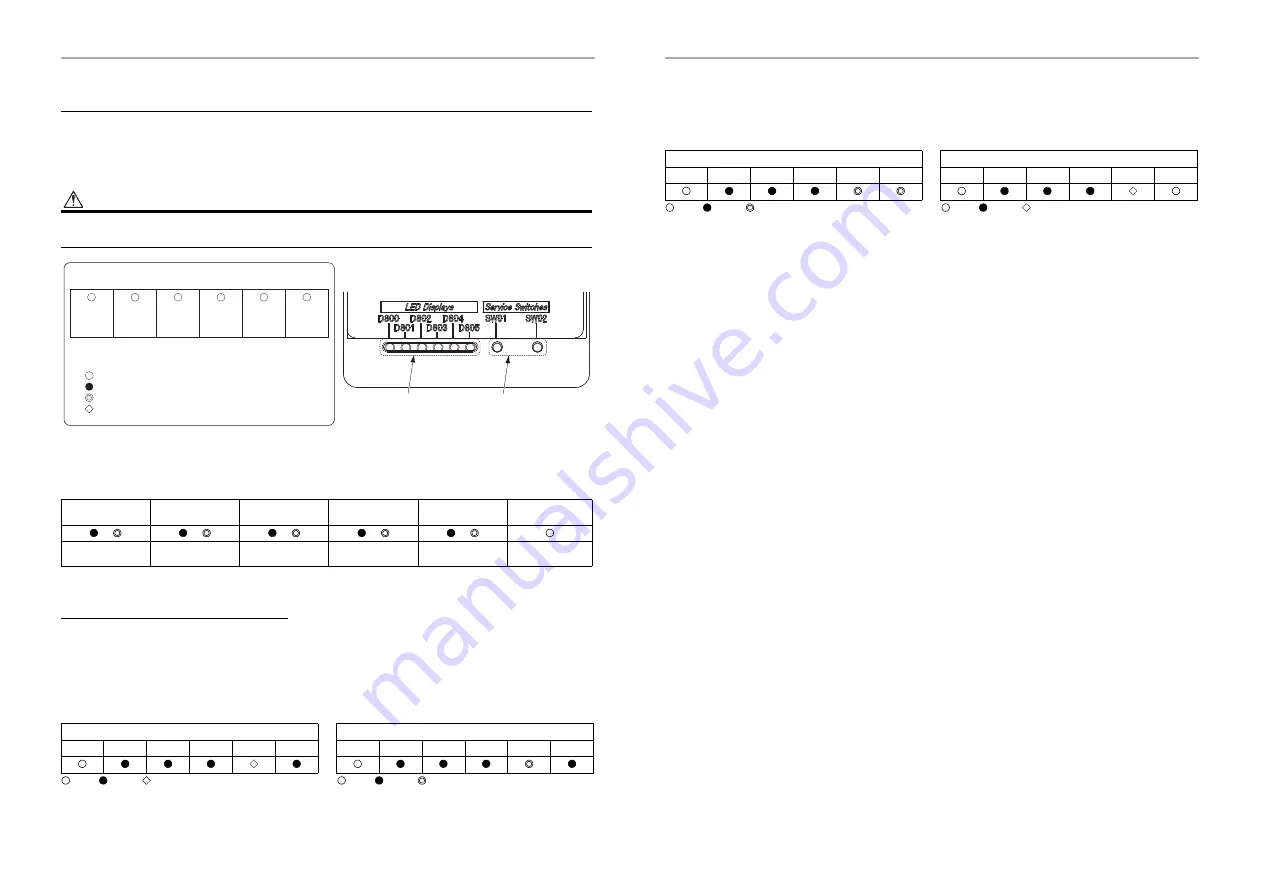

* In the initial LED display status, D805 is lighted as shown on the table below. If the initial status is not established

(if D805 is flashing), hold down the SW01 and SW02 service switches simultaneously for at least 5 seconds to

return the LED displays to the initial status.

LED display initial status

* In order to reduce standby power, the LED indication may be turned off even when the power is on. When either

SW01 or SW02 is pressed, the LED is displayed.

Steps taken to recover the refrigerant

1. Operate the Hydro Unit in the pump mode.

2. Check that the LED displays are placed in their initial status. If not, place them in the initial status.

3. Hold down SW01 for at least 5 seconds, and check that D804 flashes slowly. (Fig. 1)

4. Press SW01 once to set the LED displays (D800 to D805) to the “refrigerant recovery LED display” shown below.

(Fig. 2)

(Fig. 1)

(Fig. 2)

: ON, : OFF, : Slow flashing

: ON, : OFF, : Rapid flashing

5. Press SW02 to set D805 to rapid flashing. (Each time SW02 is pressed, D805 is switched between rapid flashing

and OFF.) (Fig. 3)

D800

(Yellow)

D801

(Yellow)

D802

(Yellow)

D803

(Yellow)

D804

(Yellow)

D805

(Green)

or

or

or

or

or

OFF or Rapid

flashing

OFF or Rapid

flashing

OFF or Rapid

flashing

OFF or Rapid

flashing

OFF or Rapid

flashing

ON

LED displays indicated when step 3 is taken

Refrigerant recovery LED display

D800

D801

D802

D803

D804

D805

D800

D801

D802

D803

D804

D805

:

:

:

:

D800

D801

D802

D803

D805

D804

LED displays

Service switches

LED displays

(Yellow)

(Green)

(Yellow)

(Yellow)

(Yellow)

(Yellow)

• There are four LEDs display patterns.

: ON

: OFF

: Rapid flashing (5 times/sec.)

: Slow flashing (1 time/sec.)

6. Hold down SW02 for at least 5 seconds, and when D804 flashes slowly and D805 lights, the forced cooling

operation is started. (Max. 10 minutes) (Fig. 4)

(Fig. 3)

(Fig. 4)

: ON, : OFF, : Rapid flashing

: ON, : OFF, : Slow flashing

7. After operating the system for at least 3 minutes, close the valve on the liquid side.

8. After the refrigerant has been recovered, close the valve on the gas side.

9. Hold down SW01 and SW02 simultaneously for at least 5 seconds. The LED displays are returned to the initial

status, and the cooling operation stop.

10. Turn off the power.

* If there is any reason to doubt whether the recovery was successful in the course of this operation, hold down

SW01 and SW02 simultaneously for at least 5 seconds to return to the initial status, and then repeat the steps

for recovering the refrigerant.

LED displays indicated when step 5 is taken

LED displays indicated when step 6 is taken

D800

D801

D802

D803

D804

D805

D800

D801

D802

D803

D804

D805

35-EN

36-EN

Содержание HWT-1101HRW-E

Страница 22: ...2F30251001 ...