e-STUDIO203S/203SD ADJUSTMENTS 9 - 1

[9] ADJUSTMENTS

1. Optical section

A. Copy magnification ratio adjustment

The copy magnification ratio must be adjusted in the main scanning

direction and in the sub scanning direction. To adjust, use TC 48-

01.

(1)

Outline

The main scanning (front/rear) direction magnification ratio adjust-

ment is made manually.

The adjustment is made by manual key operations. (The zoom data

register set value is changed for adjustment.)

The magnification ratio in the sub scanning direction is adjusted by

changing the carriage (scanner) scanning speed.

(2)

Main scanning/sub scanning direction

magnification ratio adjustment

a. Cases when the adjustment is required

1) When the main PWB is replaced.

2) When the EEPROM in the main PWB is replaced.

3) When "U2" trouble occurs.

4) When repairing or replacing the optical section.

b. Necessary tools

• Scale

c. Main scanning direction adjustment procedure

1) Set the scale vertically on the document table. (Use a long

scale for precise adjustment.)

2) Set the copy magnification ratio to 100%.

3) Make a copy on A4 or 81/2" x 11" paper.

4) Measure the length of the copied scale image.

5) Calculate the main scanning direction magnification ratio.

Main scanning direction magnification ratio

6) Check that the copy magnification ratio is within the specified

range. If it is not within the specified range, perform the follow-

ing procedures.

7) Execute TC 48-01 to select the main scanning direction copy

magnification ratio adjustment mode.

To select the adjustment mode, use the [

←

/

→

] key.

8) Enter the new set value of main scanning direction copy magni-

fication ratio with the copy quantity set key, and press the

[START] key.

9) Change the set value and repeat the adjustment until the ratio is

within the specified range.

When the set value is changed by 1, the magnification ratio is

changed by 0.1%.

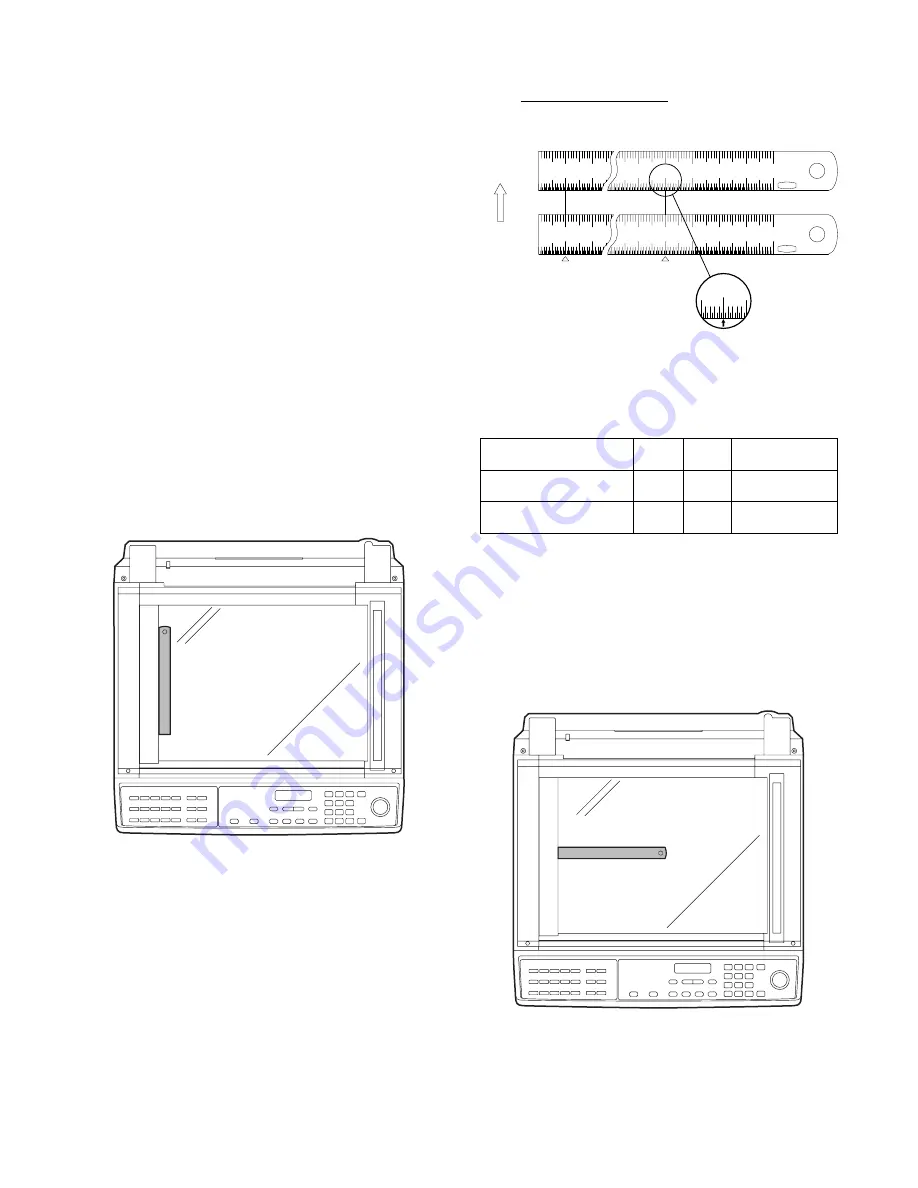

d. Sub scanning direction adjustment procedure

1) Set the scale on the document table as shown below. (Use a

long scale for precise adjustment.)

=

Copy image dimensions

X 100 (%)

Original dimension

Mode

Display

item

Default

value

LED

Main scan direction

magnification ratio

F-R

50

PRINT mode lamp

OC mode sub scan

direction magnification ratio

SCAN

50

SCAN mode lamp

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDENED

STAINLESS

Shizuoka

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDENED

STAINLESS

Shizuoka

110

10

20

10

20

(When a 100mm scale is used as the original.)

Paper feed

direction

Reference

Comparison point

Original (Scale)

Copy