___________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

Factor

Possible Problem/Correction

8. Height of cut.

All cutting units set at same height of cut. Bench set

height of cut and actual (effective) height of cut are

different. Effective height of cut depends on cutting

unit weight, counterbalance spring adjustment, cut

ting unit accessories and turf conditions.

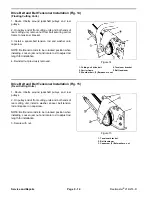

9. Rear roller parallel to reel.

Check and adjust as necessary.

10. Front roller adjustment.

Check and adjust as necessary.

11. Roller scraper and comb adjustment.

Set scraper for 1/32 in. clearance from roller. Set

comb the same on all cutting units for height of cut

and turf conditions. Must be same height at both

ends of comb.

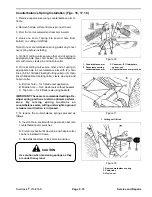

12. Stability and position of bedbar.

Check bedbar bushings and nylon flange bushings

for wear or damage and replace if necessary.

Check adjustment knob to make sure detent holds

adjustment. Repair if necessary.

Check to make sure adjustment knob/pivot assembly

is centered in bedbar arm yoke so that an equal gap

exists on each side of pivot housing before pivot

screws are installed. Make sure bedknife adjustment

knob/pivot assembly is held firmly in place between

bedbar arm yoke.Tighten pivot set screws if

necessary.

13. Number of reel blades/reel speed.

Use cutting unit model with correct number of blades

and proper pulley size for clip frequency and opti

mum height of cut range.

14. Cutting unit alignment.

Check alignment on all cutting units. Adjust or repair

as necessary. Check lift arms for damage, binding or

bushing wear. Repair if necessary.

15. Roller condition

All rollers must rotate freely. Grease when needed or

repair bearings if necessary.

Reelmaster

®

216/216-D

Page 9 - 5

Troubleshooting

Содержание reelmaster 216

Страница 2: ...This page is blank ...

Страница 4: ...This page is blank ...

Страница 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Страница 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Страница 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Страница 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Страница 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Страница 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Страница 74: ...Wiring Schematics Reelmaster 216 S N 99999 Below Wiring Schematics Page 6 2 Reelmaster 216 216 D ...

Страница 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Страница 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Страница 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Страница 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Страница 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Страница 143: ...This page is blank ...

Страница 144: ...Commercial Products The Toro Company ...