remove dirt, but do not twist it, as the foam

may tear.

B.

Dry the foam element by wrapping it in

a clean rag. Squeeze the rag and foam

element to dry it, but do not twist it, as the

foam may tear.

C.

Saturate the foam element with clean

engine oil. Squeeze the element to remove

excess oil and to distribute the oil.

Note:

A foam element that is damp with

oil is desirable.

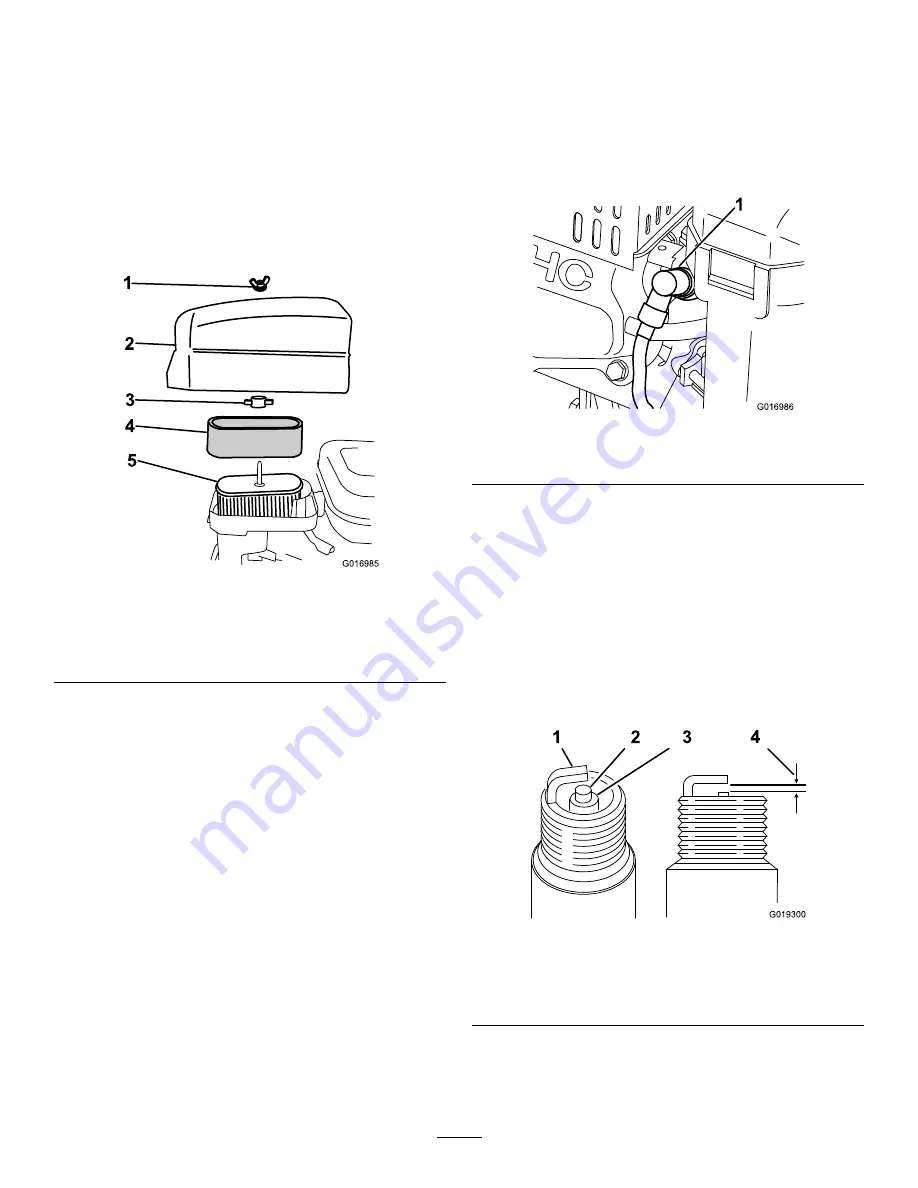

g016985

Figure 32

1.

Wing nut

4.

Foam element

2.

Air-cleaner cover

5.

Paper element

3.

Plastic wing nut

5.

Check the condition of the paper element. Clean

it by gently tapping or replace it as necessary.

Important:

Do not use compressed air to

clean the paper element.

6.

Install the foam element, paper element, and

air-cleaner cover.

Important:

Do not operate the engine

without the air-cleaner element, as extreme

engine wear and damage can result.

Servicing the Spark Plug

Service Interval:

Every 100 hours

Use an NGK BR6HS spark plug or equivalent. The

correct air gap is 0.6 to 0.7 mm (0.024 to 0.028 inch).

1.

Pull the molded wire off the spark plug (

g016986

Figure 33

1.

Spark-plug wire

2.

Clean around the spark plug and remove the

plug from the cylinder head.

Important:

Replace a cracked, fouled, or

dirty spark plug. Do not sand blast, scrape,

or clean the electrodes because engine

damage could result from grit entering the

cylinder.

3.

Set the air gap at 0.6 to 0.7 mm (0.024 to 0.028

inch) as shown in

. Install the correctly

gapped spark plug and tighten it firmly to 23

N∙m (17 ft-lb).

g019300

Figure 34

1.

Center-electrode insulator

3.

Air gap—0.6 to 0.7 mm

(0.024 to 0.028 inch)

2.

Side electrode

29