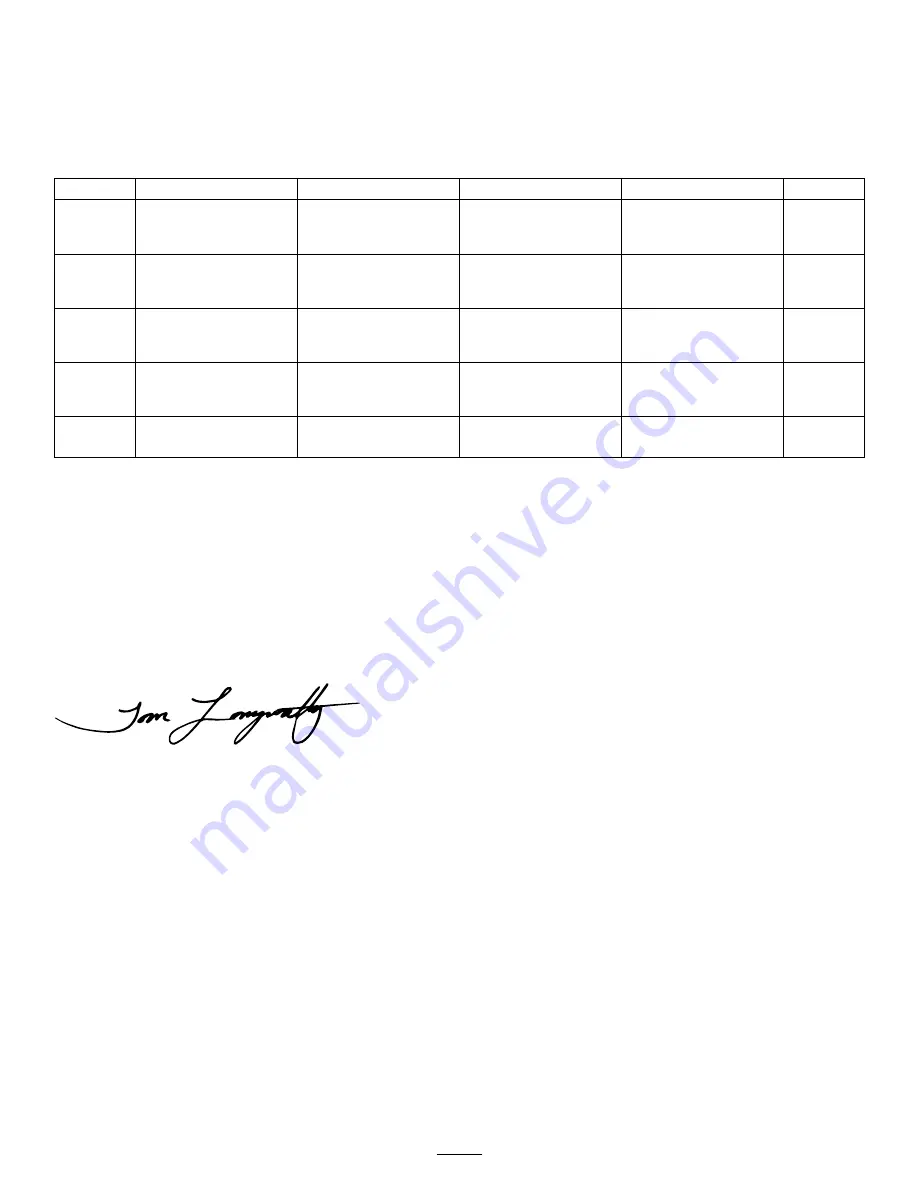

Declaration of Incorporation

The Toro Company, 8111 Lyndale Ave. South, Bloomington, MN, USA declares that the following unit(s)

conform(s) to the directives listed, when installed in accordance with the accompanying instructions onto certain

Toro models as indicated on the relevant Declarations of Conformity.

Model No.

Serial No.

Product Description

Invoice Description

General Description

Directive

03188

407900000 and Up

5-Blade 27-inch DPA

Edge Series Cutting Unit,

Reelmaster 3100-D Series

Traction Unit

RM3100 27IN 5-BLADE

(RR) ES DPA CU

Cutting Unit

2006/42/EC

03189

407900000 and Up

8-Blade 27-inch DPA

Edge Series Cutting Unit,

Reelmaster 3100-D Series

Traction Unit

RM3100 27IN 8-BLADE

(RR) ES DPA CU

Cutting Unit

2006/42/EC

03190

407900000 and Up

11-Blade 27-inch DPA

Edge Series Cutting Unit,

Reelmaster 3100-D Series

Traction Unit

RM3100 27IN 11-BLADE

ES (RR) DPA CU

Cutting Unit

2006/42/EC

03191

407900000 and Up

8-Blade 32-inch DPA

Edge Series Cutting Unit,

Reelmaster 3100-D Series

Traction Unit

RM3100 32IN 8-BLADE

ES (RR) DPA CU

Cutting Unit

2006/42/EC

03192

400000000 and Up

27-inch 8-Blade EdgeSeries

DPA Cutting Unit, Reelmaster

3105-D Traction Unit

RM3105 27IN, 8BLD RR ES

NO FRT ROLLER CU

Cutting Unit

2006/42/EC

Relevant technical documentation has been compiled as required per Part B of Annex VII of 2006/42/EC.

We will undertake to transmit, in response to requests by national authorities, relevant information on this partly

completed machinery. The method of transmission shall be electronic transmittal.

This machinery shall not be put into service until incorporated into approved Toro models as indicated on the

associated Declaration of Conformity and in accordance with all instructions, whereby it can be declared in

conformity with all relevant Directives.

Certified:

Authorized Representative:

Marcel Dutrieux

Manager European Product Integrity

Toro Europe NV

Nijverheidsstraat 5

2260 Oevel

Belgium

Tom Langworthy

Engineering Director

8111 Lyndale Ave. South

Bloomington, MN 55420, USA

June 7, 2021