Note:

Adjusting 1 side of the cutting unit affects

the other side, the 2 clicks will provide clearance

for when the other side is adjusted.

Note:

If starting with a large gap, both sides

should initially be drawn closer by alternately

tightening the right and left sides.

7.

Slowly

rotate the reel so that the same blade

that you checked on the right side is crossing

the bedknife approximately 25 mm (1 inch) in

from the end of the bedknife on the left side of

the cutting unit.

8.

Turn the left bedbar adjuster clockwise until the

shim can be slid through the reel to bedknife

gap with light drag.

9.

Return to the right side and adjust as necessary

to get light drag on the shim between the same

blade and bedknife.

10.

Repeat steps

and

until the shim can be slid

through both gaps with slight drag, but 1 click in

on both sides prevents the shim from passing

through on both sides.

Note:

The bedknife is now parallel to the reel.

Note:

This procedure should not be needed

on daily adjustments, but should be done after

grinding or disassembly.

11.

From this position (i.e., 1 click in and shim not

passing through) turn the bedbar adjusters

clockwise 1 click each.

Note:

Each click turned moves the bedknife

0.022 mm (0.0009 inch).

Do not overtighten

the adjusting screws.

12.

Test the cutting performance; refer to

the Cutting Unit (page 8)

.

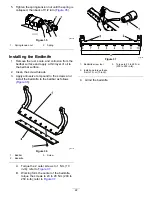

Adjusting the Rear Roller

1.

Adjust the rear roller brackets (

) to the

desired height-of-cut range by positioning the

required amount of spacers below the side-plate

mounting flange (

) per the HOC Chart.

g003324

Figure 11

1.

Spacer

3.

Side-plate mounting flange

2.

Roller bracket

2.

Raise the rear of the cutting unit and place a

block under the bedknife.

3.

Remove the 2 nuts securing each roller bracket

and spacer to each side-plate mounting flange.

4.

Lower the roller and screws from the side-plate

mounting flanges and spacers.

5.

Place the spacers onto the screws on the roller

brackets.

6.

Secure the roller bracket and spacers to

underside of side plate mounting flanges with

the nuts previously removed.

7.

Verify that the bedknife-to-reel contact is correct.

Tip the mower to expose the front and rear

rollers and bedknife.

Note:

The position of the rear roller to the reel

is controlled by the machining tolerances of the

assembled components; therefore, paralleling is

not required. A limited amount of adjustment is

possible by setting the cutting unit on a surface

plate and loosening the side-plate mounting cap

screws (

). Adjust and tighten the cap

screws. Torque the cap screws to 37 to 45 N·m

(27 to 33 ft-lb).

g020698

Figure 12

1.

Side-plate mounting cap screws

10