Servicing the HD Dual Point

Adjusters (DPA)

1.

Remove all parts (refer to the

Installation

Instructions

for the HD DPA Kit and to

2.

Apply anti-seize compound to the inside of

the bushing area on cutting unit center frame

(

).

3.

Align the keys on flange bushings to the slots in

the frame and install the bushings (

).

4.

Install a wave washer onto the adjuster shaft and

slide the adjuster shaft into the flange bushings

in the frame of the cutting unit (

5.

Secure the adjuster shaft with a flat washer and

locknut (

).

6.

Torque the locknut to 20 to 27 N∙m (15 to 20

ft-lb).

Note:

The bedbar adjuster shaft has left-hand

threads.

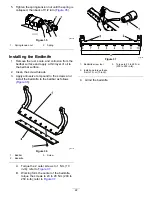

g016926

Figure 38

1.

Shaft adjuster

4.

Apply anti-seize compound

here.

7.

Apply anti-seize compound

here.

10.

Compression spring

2.

Wave washer

5.

Flat washer

8.

Bedbar-adjuster screw

11.

Spring-tension nut

3.

Flange bushing

6.

Locknut

9.

Hardened washer

7.

Apply anti-seize compound to the threads of the

bedbar-adjuster screw that fit into the adjuster

shaft.

8.

Thread the bedbar-adjuster screw into the

adjuster shaft.

9.

Loosely install the hardened washer, spring, and

spring tension nut onto the adjuster screw.

10.

Install the bedbar, positioning the mounting ears

between the washer and the bedbar adjuster.

11.

Secure the bedbar to each side plate with the

bedbar bolts (nuts on bolts) and 6 washers.

Note:

Position a nylon washer on each side of

the side-plate boss.

12.

Place a steel washer outside each of the nylon

washers (

).

13.

Torque the bedbar bolts to 37 to 45 N∙m (27 to

33 ft-lb).

14.

Tighten the locknuts until the outside steel

washer stops rotating and end play is removed

but do not overtighten or deflect the side plates.

Note:

The washers on the inside may have a

gap (

15.

Tighten the nut on each bedbar-adjuster

assembly until the compression spring is fully

compressed, then loosen the nut 1/2 turn (

23