Structure

Overview

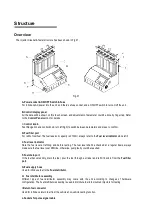

The Injector Cleaner& Tester structure has been shown in Fig.01.

Fig.01

A-Power socket & ON/OFF Switch & Fuse

For introduce AC power into the unit, and there’s a fuse socket, and a ON/OFF switch to turn on/off the unit.

B-Control/display panel

All the data will be shown on this touch screen, and adjustment of parameter could be done by finger tap. Refer

to the

Control Panel

section for details

C-

Control knob

Fast Navigation and control knob, turn left/right to switch between parameters and press to confirm.

D-Fuel filler port

For refill of test fuel. The fuel reservoir capacity is 2100ml, always refer to the

Fuel level indicator

while refill.

E-

Fuel level indicator

Note the fuel level at refilling, and before testing. The fuel level shall be checked at a regular basis, always

make sure the fuel level over MIN line, otherwise, pump faulty could be resulted.

F-Fuel drain port

If the fuel becomes dirty, drain the fuel, pour the fuel through a strainer and refill it back in from the

Fuel filler

port

.

G-Fuel supply hose

Used to introduce fuel to the

Fuel distributor

.

H- Fuel distributor assembly

Different type of fuel distributor assembly may come with the unit according to changes of hardware

configuration. The Fuel distributor assembly is used to distribute fuel into mounted injectors for testing.

I-Return fuel connector

Used for introduce return fuel from the vehicle at on-vehicle-testing function.

J-Sockets for pulse signal cable

Содержание GDI

Страница 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

Страница 16: ......