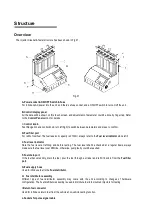

2) Mount the injectors on the couplers and install them onto the side-supply fuel distributor.

3) Mount the cross plate (1) and tighten it with bolts.

4) Mount the fuel distributor and injectors onto the fuel distributor supporter, and tighten them with two riffle screws (black).

See Fig. 06.

5) Connect the injector pulse signal wire.

6) Before doing this test, tap <

Drain

> button to drain the test liquid from the measuring cup if there is any.

7) Tap <

Uniformity/Sprayability test

> on the control panel, set the corresponding parameters and tap <

Run

> button to

start the testing.

8) When the testing is finished, Injector Cleaner & Tester will stop.

CNC3

Fig. 06

1-

Cross plate; 2-Fuel side-supply injector; 3- Coupler for fuel side-supply injector; 4,5-O-ring; 6-Side-supply fuel distributor

Note:

While testing, Injector Cleaner & Tester can drain fuel by tap <Drain> key at anytime. At default, solenoid valve

is set at the closed state. Uniformity test can be done at this state. When <drain> key is pressed, solenoid

valve will drain oil for 60 seconds.

The default cylinder number of the system is 0, which means that all injectors are working when Injector

Cleaner & Tester is running. A specific cylinder can be selected by setting the number of the cylinder.

The System Pressure, RPM, Pulse can be adjusted during testing.

Keep the fuel level to at least 30 ml while testing. Foam will be produced in the liquid during injection. In order

to prevent spillover, set the related parameter with reference to the following formula :Pulse width(ms)

×

time(s)

×

speed(rpm) / 120

≤

18000

This function is for checking the uniformity of each cylinder. Injecting difference of all injectors on one

vehicle should be kept within 2% during uniformity testing.

Reverse flush

Injector Cleaner & Tester can also perform reverse flush by connecting with flush-back adaptor at [Uniformity/Spray-ability

test] mode. Reverse flush is a way to clean the injectors with the test liquid flowing from the outlet to the inlet of the injector.

Reverse flush may remove the dirt inside the injector or the injector Strainer (Only for the top fuel supply injector).

Procedures:

1) Choose a reverse flush coupler and proper O-ring, and mount them under the fuel distributor.

2) Install the injectors in reverse direction (outlet upward, and inlet downward).

3) Choose a proper coupler according to the shape of the injector and put it under the injector.

4) Install the fuel distributor and the injector on the fuel distributor supporter with a proper adjustable screw and knurled

nuts, and tighten two riffle screws (black). See Fig. 07.

5) Connect the injector pulse signal wire.

6) Tap <

Injecting Flow Test

> icon, and tap [Run] button to start cleaning.

7) When the cleaning is over, Injector Cleaner & Tester will automatically stop.

Note:

The system pressure can be adjusted when performing reverse flush.

It is advised to tap <Drain> key to avoid spillover of test liquid during reverse flush.

Fig. 07

Содержание GDI

Страница 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

Страница 16: ......