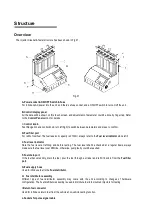

3) The connection of engine fuel pipes has been shown in “Connecting” below.

4) Tap <

On-vehicle cleaning

> icon on the control panel, and set the time and tap <

Run

> button to start the test, and then

start the engine with park gear applies.

5) Refer to specifications required by various vehicle types to adjust system pressure.

Fig.08

1- Fuel-return connector; 2- Fuel-return hose from engine; 3-Fuel-inlet hose to engine

Connecting

The hose line connection of the engine with return hose is shown as in Fig.09.

1) Disconnect the connections of fuel supply hoses (C

、

D) and fuel return hoses (A

、

B) of the engine fuel system (wrap the

connector with towel when disconnecting the connector). Choose proper connectors and connect them to the B end and

C end separately, and then connect the other ends to corresponding return hose and outlet hose of the unit. See Fig.09.

2) Connect the disconnected other ends (A

、

D) with proper hose, or remove the fuel pump fuse, or disconnect the power

cable of engine fuel pump.

Fig.09

1- Injector Cleaner & Tester; 2-Engine; 3- Fuel-return hose from engine; 4- Fuel-inlet hose to engine; 5-Auto filter; 6-Engine

fuel supply hose; 7-Engine fuel return hose; 8- Auto fuel pump; 9-Auto tank

Without return hose connecting:

The hose line connection of the engine without return hose is shown as in Fig.10.

1) Disconnect the fuel supply hoses (E, F) of engine fuel system (wrap the connector when disconnecting the connector),

and then choose a proper connector and connect it to the E end. Reconnect the fuel outlet hose of the unit well and

make the fuel return hose hanging. See Fig.10.

2) Stop the other end of the disconnected end (F) with a proper stopper, (use when the fuel pump has the fuel return

function only) or remove the fuse of fuel pump or disconnect the power cable of fuel pump.

Fig.10

1- Injector Cleaner & Tester; 2-Engine; 3-stopper; 4- Fuel-inlet hose to engine; 5-Auto tank;6-Auto filter; 7- Engine fuel supply

hose; 8-Auto fuel pump;

Note:

Содержание GDI

Страница 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

Страница 16: ......