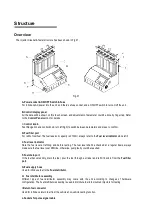

Functions

Ultrasonic cleaning:

To perform simultaneous cleaning on several injectors and to remove the carbon deposits on

the injector completely.

Uniformity/Spray-ability test:

To test the uniformity of injecting amount of each injector, and to monitor the spraying

status of each injector with the help of backlight. This test is also for reverse flush.

Leakage test:

To test the sealing and dribbling conditions of injectors under system pressure.

Injecting flow test:

To check the injecting amount of the injector in 15 seconds of constant injection.

Automatic test

: To test injectors by simulating different working conditions.

On-vehicle cleaning:

The unit is equipped with various adapters and couplers that facilitate cleaning on the injectors

on vehicle.

Features

Adopting the powerful ultrasonic cleaning technology, the equipment offers complete cleaning to the injectors.

Fuel pressure control through microcomputer offers stable pressure control and large adjustable range, which is

suitable for all EGI vehicles and can help to achieve automatic cleaning and testing of injectors.

With the help of microcomputer control and digital display, the equipment makes possible automatic cleaning, testing

injectors and real-time monitoring of the dynamic values.

Automatic fuel draining through preset programs for some test items. Test liquid/detergent can also be drained by

pushing a button on the control panel after the test.

Adopting humanization design can make the system pressure fast restored to the default values.

Specifications

Working conditions:

Temperature: -10~+40

℃

;

Relative humidity:

<

85%;

Intensity of outer magnetic field:

<

400A/m;

No flame within 2 meters.

Specifications:

Main unit power supply: AC110~220V±10%, 50/60Hz;

Main unit power: 150W

Dimension of main unit: 27cm x 31 cm x 34cm

Ultrasonic cleaner power: 60W;

Fuel pressure:0-10bar

Simulated RPM range: 20

~

10000rpm;

Pulse width: 0.5

~

25ms; step 0.1 ms;

Uniformity/Spray-ability test duration: 1~20min

Leakage test duration: 1~30min

Injecting flow test duration: 3~120s

Automatic drain: 60s

Pressure unit: Bar, Psi, Kpa, mmHg, Kg/cm

2

Delivery dimension: 300x340x400mm

Delivery Weight: 12kg

(Varies according to configuration)

Содержание GDI

Страница 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

Страница 16: ......