Model: TTT-710

8.4 Waste Solution Flow Passage Maintenance and Inspection

- 94 -

8.4 Waste Solution Flow Passage Maintenance and

Inspection

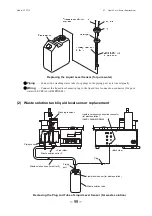

(1) Waste solution flow passage inspection

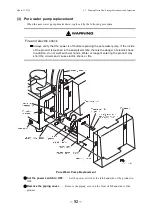

(a) The washing water (pure water) is drained straight down from the drain port at the bottom of

washing reservoir and overflow port to the drain block and discharged into the waste solution tank

through a waste solution hose.

(b) When the washing water (pure water) is drained for 10 seconds, about 100mL of waste solution is

discharged. Before using the product, check that the waste solution level inside the tank is

sufficiently low so that the tank will not become full during continuous measurement.

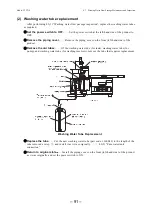

(c) Remove the piping cover at the front (left-hand side) of the product and check that the following

waste solution hoses (3 hoses) are not deteriorated, damaged, or bent. Especially check that there is

no floating up at the waste solution hose (for outlet 2). If there is a problem, replace the waste

solution hose.

>>

8.4(2) “Waste solution hose replacement”

•

Waste solution hose (for outlet 1): Between washing reservoir (waste solution outlet 1) and waste

solution block

•

Waste solution hose (for overflow port): Between washing reservoir (overflow port) and waste

solution block

•

Waste solution hose (for outlet 2): Between waste solution block (waste solution outlet 2) and

waste solution tank (piping port)

Visual Inspection of Waste Solution Hose

(d) After checking that there are no problems at (c) above, operate the pure water pump and check that

the water is smoothly discharged from waste solution outlets 1 and 2 at washing reservoir.

•

Pure water pump operation method

⋅⋅⋅

>>

6.1 (4) “Pumps and waste water valve operation and

tank liquid level judgment”

Содержание TTT-710

Страница 115: ... 114 ...

Страница 117: ... 116 ...