TIMBERWOLF

TW PTO 150H

17

SERVICE INSTRUCTIONS

1.

Lubricate regularly. At least every 16 hours on

coupling grease nipples and 8 hours on all other

lubricated points.

Replace prop shaft shear bolts only with correct

grade of bolt available from the shaft supplier.

1

SEE SEPARATE PROP SHAFT INSTRUCTION SHEET FOR FULL DETAILS.

Further information on the safe use of PTO shafts can be found in HSE leaflet AS 24

NOTE: This should be done regularly. In dirty and dusty conditions or during periods of hard

work it should be weekly. If the bearings and splines are allowed to run dry premature wear will

occur resulting in a breakdown and the need for replacement parts. This failure is not warranty.

Early signs of insufficient grease includes squeaking or knocking rollers.

1.

Remove bolt and washer retaining roller box guard and lift guard (see

diagram on page 16).

2.

Locate two grease nipples; one in the centre of each roller shaft.

3.

Use a pump action grease gun to apply a generous amount of grease

to each roller drive.

DO NOT USE GRAPHITE BASED GREASE.

After applying grease, to penetrate all the bearing surfaces thoroughly,

start the machine and operate the rollers for 20 seconds. Switch off the

machine. Repeat this greasing/running procedure a further 3 times.

4.

Close roller box guard making sure that it is located over the retaining

bracket, and ensure bolt and washer are tightened.

NOTE: This should be done regularly. In dirty or dusty conditions or during periods of hard

work it should be done weekly. If the slides become dry the top roller will tend to hang up and

the pulling-in power of the rollers will be much reduced. Excessive wear will ensue.

1.

Turn the tractor off and remove the ignition keys.

2.

Ensure machine has come to a complete stop - remove power cable.

3.

Remove the bolt and washer retaining roller box guard and lift guard.

4.

Remove the two springs on the roller box slide.

5.

NOTE: Rollerbox slide weighs in excess of 20kg.

Lift the top

roller and wedge a suitably sized piece of wood to hold in place.

6.

Apply thin grease with a brush to each slide on roller box and

on inner cheeks of slider.

DO NOT USE GRAPHITE BASED

GREASE.

7.

NOTE: Rollerbox slide weighs in excess of 20kg.

Remove

wedge, lower roller box slide and replace springs.

8.

Close roller box guard making sure that it is located over the

retaining bracket, and ensure bolt and washer (as note 3) are tightened.

9.

Refit power cable.

6

3

2

5

4

GREASE THE ROLLER SPLINE AND BEARING

PTO DRIVE SHAFT MAINTENANCE

GREASE THE ROLLER BOX SLIDES

Содержание tw pto 150h

Страница 22: ...TIMBERWOLF TW PTO 150H 21 EXAMPLE IDENTIFICATION PLATE...

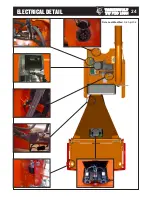

Страница 25: ...TIMBERWOLF TW PTO 150H 24 Date Last Modified 3rd April 06 ELECTRICAL DETAIL...

Страница 28: ...blank page...