START tractor.

GENTLY engage PTO clutch.

INCREASE tractor revs until tractor PTO

speed = 540 rpm.

DO NOT RUN ON ANY OTHER PTO SPEED

SETTING.

CHECK that chipper is running smoothly.

RELEASE the catch on the feed tray and lower.

PULL to release the red stop button, perform

safety bar tests (as shown on page 9).

PRESS the green control button. The rollers will

commence turning.

STAND to one side of the feed funnel.

PROCEED to feed material into the feed funnel.

Push the

RED STOP

button or push the

RED SAFETY BAR

(whichever is the quickest for you

to reach). Turn off tractor ignition key or operate tractor stop lever.

The emergency stop will prevent any more material being fed into the chipper. The rotor will still be

turning. The tractor must be disengaged or powered down to stop the rotor.

Wood up to 150 mm diameter can be fed into the feed funnel. Put the butt end in first and engage it with

the feed roller. The hydraulic feed rollers will pull the branch into the machine quite quickly. Large

diameter material will have its feed rate automatically controlled depending on the tractor power available.

Sometimes a piece of wood that is a particularly awkward shape is too strong for the feed rollers to

break. This will cause the top roller to either bounce up and down on the wood or both rollers to stall.

If this occurs, press the

BLUE REvERSE

button until the material has been released. Pull the

material out of the feed funnel and trim it so the chipper can handle it.

Both feed rollers should always turn at the same speed. If one or both rollers stop or suddenly slow

down it may be that a piece of wood has become stuck behind one of the rollers. If this occurs press

the

BLUE REvERSE

button and hold for 2 seconds - then repress

GREEN FEED

button. This should

enable the rollers to free the offending piece of material and continue rotation at the correct speed. If

the rollers continue to stall in the 'forward feed' or 'reverse feed' position push the

RED STOP BUTTON

,

turn tractor engine off, remove ignition key and investigate.

STARTING TO CHIP

WARNING

Ensure feed funnel, feed tray, feed roller guard, prop shaft guards and

access covers are fitted and secure, and that the discharge unit is

fitted and pointing in a safe direction.

EMERGENCY STOPPING

CHIPPING

TIMBERWOLF

TW PTO 150H

11

OPERATING INSTRUCTIONS

BLADE WEAR

The most important part of using a wood chipper is keeping the cutter blades sharp. Timberwolf

chipper blades are hollow ground to an angle of 40 degrees. When performing daily blade checks

ensure blade edge is sharp and free from chips, if there is any evidence of damage, or the edge is “dull”

change the blade(s). The TW PTO 150H is fitted with 2 blades 101mm (4") long. They are 44 mm wide

when new. A new blade should chip for up to 25 hours before it requires sharpening. This figure will

be drastically reduced by feeding the machine with stony, sandy or muddy material.

As the blade becomes blunt, performance is reduced. With increased stress and load on the machine

the chips will become more irregular and stringy. At this point the blade should be sent to a reputable

blade sharpening company. The blade can be sharpened several times in its life. A wear mark on the

reverse side indicates the safe limit of blade wear. Replace when this line is exceeded.

The machine is also fitted with a static blade (anvil). It is important that the anvil is in good condition

to allow the cutting blades to function efficiently. Performance will be poor, even with sharp cutter

blades, if the anvil is worn.

Содержание tw pto 150h

Страница 22: ...TIMBERWOLF TW PTO 150H 21 EXAMPLE IDENTIFICATION PLATE...

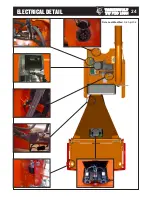

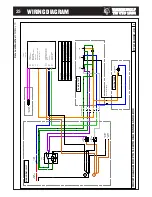

Страница 25: ...TIMBERWOLF TW PTO 150H 24 Date Last Modified 3rd April 06 ELECTRICAL DETAIL...

Страница 28: ...blank page...