TIMBERWOLF

TW PTO 150H

15

SERVICE INSTRUCTIONS

ALWAYS IMMOBILISE THE TRACTOR BEFORE UNDERTAKING ANY MAINTENANCE WORK ON

THE CHIPPER.

ALWAYS stop the tractor engine before installing or removing the prop shaft.

HANDLE blades with extreme caution to avoid injury. Gloves should always be worn when

handling the cutter blades.

AvOID contact with hydraulic oil.

WHENEvER possible the pump belt should be connected while changing blades, as this

will restrict sudden movement of the rotor.

THE major components of this machine are heavy. Lifting equipment must be used for

disassembly.

CLEAN machines are safer and easier to service.

Product name: Copper Ease.

Copper Ease contains no hazardous ingredients at or above regulatory disclosure limits, however,

safety precautions should be taken when handling (use of oil-resistant gloves and saftey glasses are

recommended - respiratory protection is not required). Avoid direct contact with the substance and

store in a cool, well ventilated area avoiding sources of ignition, strong oxidising agents and strong

acids. Dispose of as normal industial waste (be aware of the possible existance of regional or national

regulations regarding disposal), do not discharge into drains or rivers.

In case of fire:

in combustion the product emits toxic fumes, extinguish with alcohol or polymer foam,

carbon dioxide or dry chemical powder. Wear self-contained breathing apparatus and protective clothing

to prevent contact with skin and eyes.

FIRST AID

Skin contact:

there may be mild irritation at the site of contact, wash immediately with plenty of soap

and water.

Eye contact:

there may be irritation and redness, bathe the eye with running water for 15 minutes.

Ingestion:

there may be irritation of the throat, do not induce vomiting, wash out mouth with water.

A safety data sheet for this product can be obtained by writing to the manufacturer at the

following address: Comma Oil and Chemicals Ltd., Deering Way, Gravesend, Kent DA12 2qX.

Tel: 01474 564311, Fax: 01474 333000.

The Timberwolf PTO/150H is subject to large vibrations during the normal course of operation.

Consequently there is always an possibility that nuts and bolts will work themselves loose. It is

important that periodic checks are made to ensure the security of all fasteners. Fasteners should be

tightened using a torque wrench to the settings listed below.

Uncalibrated torque wrenches can be

inaccurate by as much as 25%. It is therefore essential that a calibrated torque wrench is used

to achieve the tightening torques listed below.

Size

Pitch

Head

Torque Ibft

Blade Bolts

M10

Standard

T50 Torx

45

Hyd Motor Retaining Bolts

M10

Standard

17mm Hex

34

Funnel Retaining Nuts

M12

Standard

17mm Hex

38

General

M8

Standard

13 mm Hex

20

General

M10

Standard

17 mm Hex

45

General

M12

Standard

19 mm Hex

65

SAFE MAINTENANCE

COPPER EASE SAFETY INFORMATION

CHECK FITTINGS

Содержание tw pto 150h

Страница 22: ...TIMBERWOLF TW PTO 150H 21 EXAMPLE IDENTIFICATION PLATE...

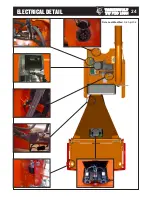

Страница 25: ...TIMBERWOLF TW PTO 150H 24 Date Last Modified 3rd April 06 ELECTRICAL DETAIL...

Страница 28: ...blank page...