TIMBERWOLF

TW PTO 150H

14

SERVICE INSTRUCTIONS

WARNING

Always immobilise the machine by stopping the tractor and removing

the ignition key before undertaking any maintenance work. When the

tractor is stopped it will be necessary to disengage the PTO so that

the rotor can be turned.

SERVICE SCHEDULE

SERVICE SCHEDULE

Check linkage points for damage or signs of fatigue.

ü

Check feed funnel, feed roller cover, rotor access cover,

discharge tube and PTO guards are securely fitted.

ü

Check safety bar mechanism

ü

Lubricate PTO shaft coupling grease nipples.

ü

Inspect blades and change if necessary.

ü

Check hoses for signs of chafing or leakage.

ü

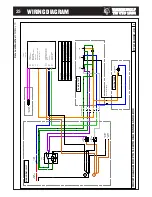

Check for loose electrical wiring

ü

Check for tightness all visible nuts bolts and

ü

other fasteners.

Check (and adjust if necessary) tension of rotor belts.

ü

ü

Check (and adjust if necessary) pump belt tension.

ü

Grease the roller box slides.

ü

Grease the roller spline and bearing.

ü

Grease hydraulic motor spline drives.

ü

Check anvil for wear.

ü

Change hydraulic oil and filter.

ü

Replace anvil

Only fit genuine Timberwolf replacement blades, screws and chipper spares. Failure to do so

will result in the invalidation of the warranty and may result in damage to the chipper, personal

injury or even loss of life.

The lifting eye is designed to lift the machine’s weight only. Do not use

hoist hook directly on the lifting eye, use a correctly rated safety shackle.

Inspect the lifting eye prior to each use - DO NOT USE IF DAMAGED.

NOTE:

Your Timberwolf wood chipper is covered by a full 12 months parts and labour warranty.

Subject to correct maintenance and proper machine usage, the bearings are guaranteed for 12 months

regardless of hours worked by the machine. In conditions of 'heavy usage' - i.e. in excess of 500 hours

per year - it is recommended that the bearings are changed annually to ensure that the machine retains

optimum working performance.

Daily

25

Hours

50

Hours

(once a month)

400

Hours

(once a year)

All the hydraulic hoses should be regularly inspected for chafing and leaks. The hydraulic system is

pressurized up to 150 Bar and thus the equipment containing it must be kept in good condition.

Identify the hoses that run to the top motor. These have the highest chance of damage as they are

constantly moving. If any hydraulic components are changed, new seals should be installed during

reassembly. Fittings should then be retightened.

(1ST

TIME)

THEN

SAFE LIFTING OF THE CHIPPER

SPARES

CHECK HOSES

RETURN TO DEALER FOR ANVIL CHANGE

Содержание tw pto 150h

Страница 22: ...TIMBERWOLF TW PTO 150H 21 EXAMPLE IDENTIFICATION PLATE...

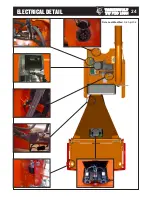

Страница 25: ...TIMBERWOLF TW PTO 150H 24 Date Last Modified 3rd April 06 ELECTRICAL DETAIL...

Страница 28: ...blank page...