Form RZ-NA-I-FT, Page 8

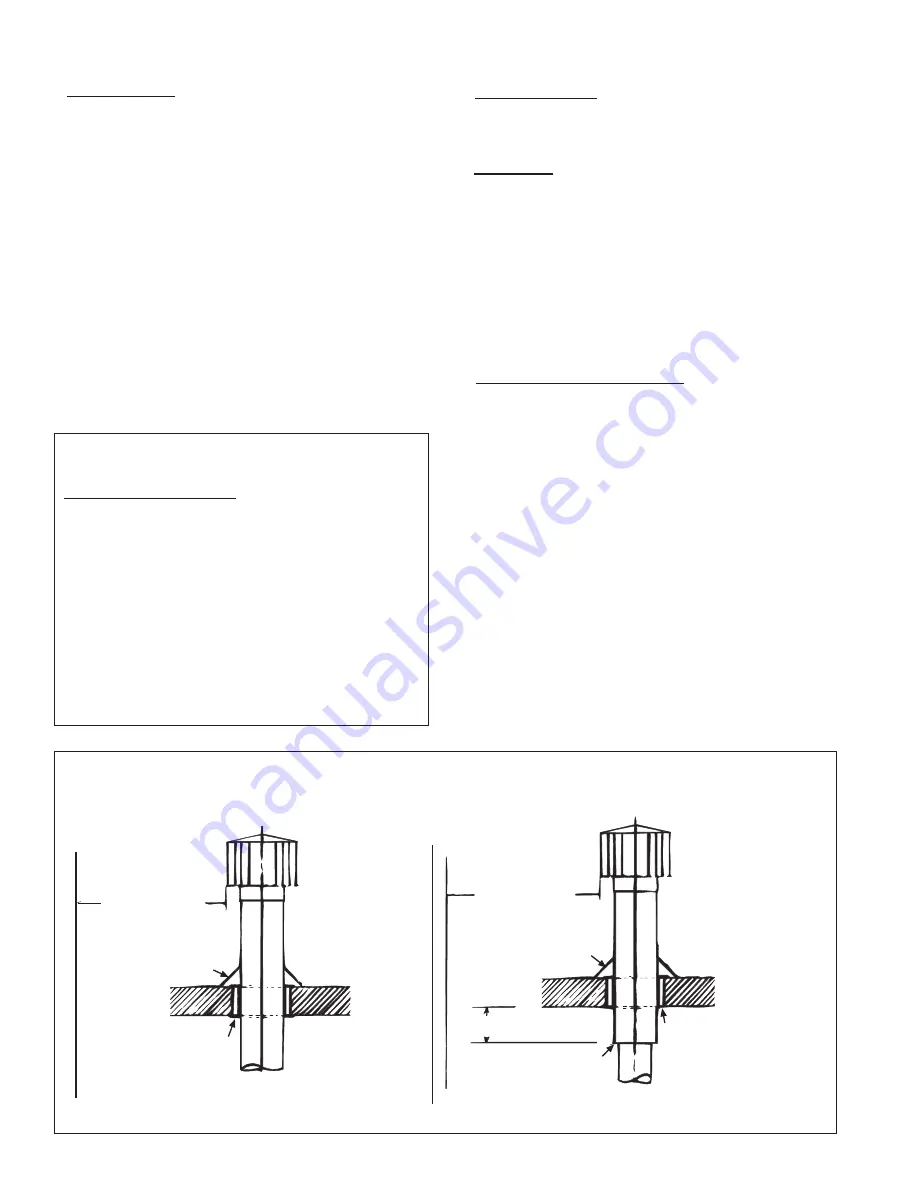

Figure 7A - Vertical Vent Terminals

11. Venting Requirements (cont'd)

6 (2M) minimum

6 (2M) minimum

Approved clearance thimble

for single-wall vent pipe is

required when flue pipe

extends through

combustible materials.

Parapet or Adjoining Building

Vertical flue extension to

be 6 (152mm) higher than

anticipated snow depth but

no less than 2 feet (610mm)

above the roof.

Vertical pipe extension

must be insulated.

Roof Flashing

Roof - pitched

from 0 to 45°

Vertical flue extension

to be 6 (152mm) higher

than anticipated snow

depth but no less than

2 feet (610mm) above the

roof.

6 (152mm) minimum

Roof Flashing

Roof - pitched

from 0 to 45°

Approved clearance thimble

is required when flue pipe

extends through combustible

materials. Follow the require-

ments of the double-wall pipe

manufacturer.

Follow instructions above

to join single and double-wall

pipe and to seal the connection.

Parapet or Adjoining Building

Single-Wall Vent Run

and Single-Wall

Terminal End

Single-Wall Vent Run

and Double-Wall

Terminal End

5. Vent System Support

- Lateral runs should be supported every six

feet using a non-combustible material, such as strap steel or chain. Do

not rely on the heater for support of either horizontal or vertical vent

pipe.

6. Condensation

- On Model Sizes 30 and 45 only, if a single-wall vent

pipe run exceeds 15 feet (4.6 M) of straight length, it is recommended

that the pipe be insulated along its entire length with a minimum of 1/2"

foil-faced fiberglass, 1-1/2# density insulation rated for 250°F.

On all Model Sizes, any length of single-wall vent pipe exposed to cold

air or run through an unheated area or an area with an ambient tempera-

ture of 45°F or less must be insulated along its entire length with a

minimum of 1/2" foil-faced fiberglass, 1-1/2# density insulation. Model

Sizes 30 and 45 require insulation rated for 250°F; Model Sizes 60-300

require insulation rated for 400°F.

Where extreme conditions are anticipated, install a means of condensate

disposal.

7. Vent Terminal (Pipe and Vent Cap) -

The vent system must be

terminated with the type of vent cap approved for use with this heater.

The vent cap must be the same size as the vent pipe (vent pipe is either

3", 4", 5" or 6" diameter). Heaters must be equipped with the heater

manufacturer's vent cap, a Type L Breidert

Air-x-hauster

®

vent cap, or

equivalent. A different style vent cap could cause nuisance problems or

unsafe conditions.

See the illustrations in Figures 7A and 7B for requirements of vertical

and horizontal vent termination. The vent terminal pipe may be either

single-wall or double-wall (Type B). If double-wall pipe is used in the

vent terminal with a single-wall vent run, follow the instructions in

"Vent System Joints" (in the left column) to attach the vent cap and to

connect the double-wall pipe to the single-wall vent pipe run.

4. Vent System Joints

- Vent system joints depend on the type of pipe

being used (See "Vent Pipe" requirements, No.1).

•

If using single wall, 26-gauge or heavier galvanized pipe, secure

slip-fit connections using sheetmetal screws or rivets. Seal pipe joints

either with tape suitable for 550°F (such as Option FA1, P/N 98266)

or high-temperature silicone sealant.

If using single-wall pipe to install a horizontal vent on a residential

application (Figure 6), make the elbow rigid by adding a light bead

of silicone sealant to the full circumference of

all

elbow section

joints.

•

If using Category III vent pipe, follow the pipe manufacturer's in-

structions for joining pipe sections. When attaching Category III

pipe to the venter outlet or the vent cap, make secure, sealed joints

following a procedure that best suits the style of Category III pipe

being used.

•

If using double-wall (Type B) vent pipe, follow the pipe

manufacturer's instructions for joining pipe sections.

For joining double-wall pipe to the venter outlet collar, increaser

collar, single-wall pipe, and/or the vent cap, follow the "boxed"

instructions below:

Instructions for attaching double-wall (Type B) vent pipe to the

venter outlet, a single-wall pipe run, or to the vent cap (use these

instructions for either full length double-wall or terminal only)

:

Hardware and Sealant Required: 3/4" long sheetmetal screws; and

a tube of silicone sealant

1) Look for the "flow" arrow on the vent pipe; attach according to

the arrow. Slide the pipe so that the venter outlet, the single-wall

pipe, or the vent cap is inside the double-wall pipe.

2) Drill a hole through the pipe into the outlet collar, the single-wall

pipe, or the vent cap. (Hole should be slightly smaller than the

sheetmetal screw being used.) Using a 3/4" long sheetmetal screw,

attach the pipe. Do not overtighten. Repeat, drilling and inserting

two additional screws evenly spaced (120° apart) around the pipe.

3) Use sealant to seal any gaps. If there is an annular opening, run a

large bead of sealant in the opening. The bead of sealant must be

large enough to seal the opening, but it is not necessary to fill the

full volume of the annular area.