Stepper Motor Demo Application

4.4.2

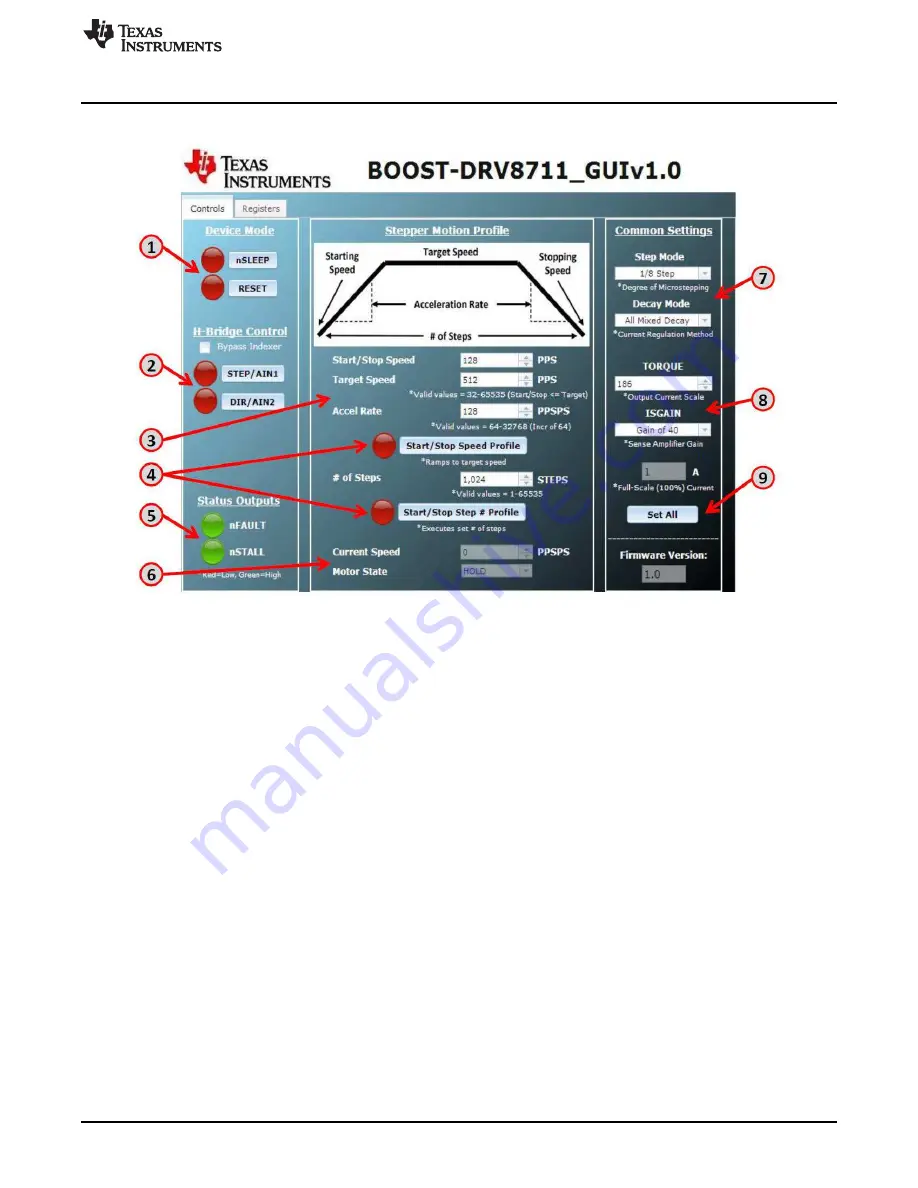

CONTROL Tab Walkthrough

Figure 12. BOOST-DRV8711 GUI CONTROL Tab

1. The nSLEEP and RESET buttons directly control the nSLEEP and RESET pins of the DRV8711. Red

indicates LOW (0 V) and green indicates HIGH (3.3 V). nSLEEP = LOW puts the DRV8711 in a low

power sleep mode. RESET = HIGH resets the internal logic and disable the H-bridge outputs.

2. The STEP and DIR buttons give you command of the stepper motor. STEP moves the motor one step,

independent of the Stepper Motion Profile. DIR selects which direction the motor is spinning.

3. The Stepper Motion Profile provides a method to spin the stepper motor in a variety of ways. It gives

you command of the starting/stopping speed, acceleration rate, target speed, and number of steps (if

using the step # profile). The units are pulses per second, or steps per second, as the DRV8711 will

move a step with every rising edge it sees.

4. The Speed Profile button (once selected) accelerates the stepper motor from the starting speed to the

target speed. The motor remains at this speed until the Speed Profile button is selected again. The

Step # Profile (once selected) moves the stepper motor the specified number of steps while attempting

to maintain the speed profile. Due to approximation errors on the MCU, the target speed may not

exactly match the target speed.

5. The nFAULT and nSTALL provide status about the motor and motor driver. The nFAULT reports on a

variety of faults for the DRV8711. A more detailed description of the various faults can be found in the

datasheet. nSTALL is a feature of the DRV8711 to detect a motor stall. This feature must be calibrated

to function properly. Please see the datasheet for additional information.

6. The Current Speed box provides information about the current speed of the speed motor. The Motor

State box indicate the status of the motor, whether it is stopped, accelerating, decelerating, and so

forth. Note that there is a slight time delay in the GUI (~ 1 second).

7. The Step Mode setting determines the microstepping level of the DRV8711. The Decay Mode

determines the decay method of the current regulation scheme. The recommended modes for stepper

motors are All Mixed and Auto Mixed Decay. The decay method is fine tuned in the Registers tab.

8. The TORQUE and ISGAIN settings, in combination with the hardware SENSE resistor, determine the

full scale current of the current regulation scheme. By adjusting these settings you can adjust the full

11

SLVU967 – May 2014

BOOST-DRV8711

Copyright © 2014, Texas Instruments Incorporated