44

44

44

44

38

RSWA User’s Guide

Weld Name Auto-Generator

If your weld names are similar, you can instruct the RSWA to name your welds for you using

the weld name Auto-Generator.

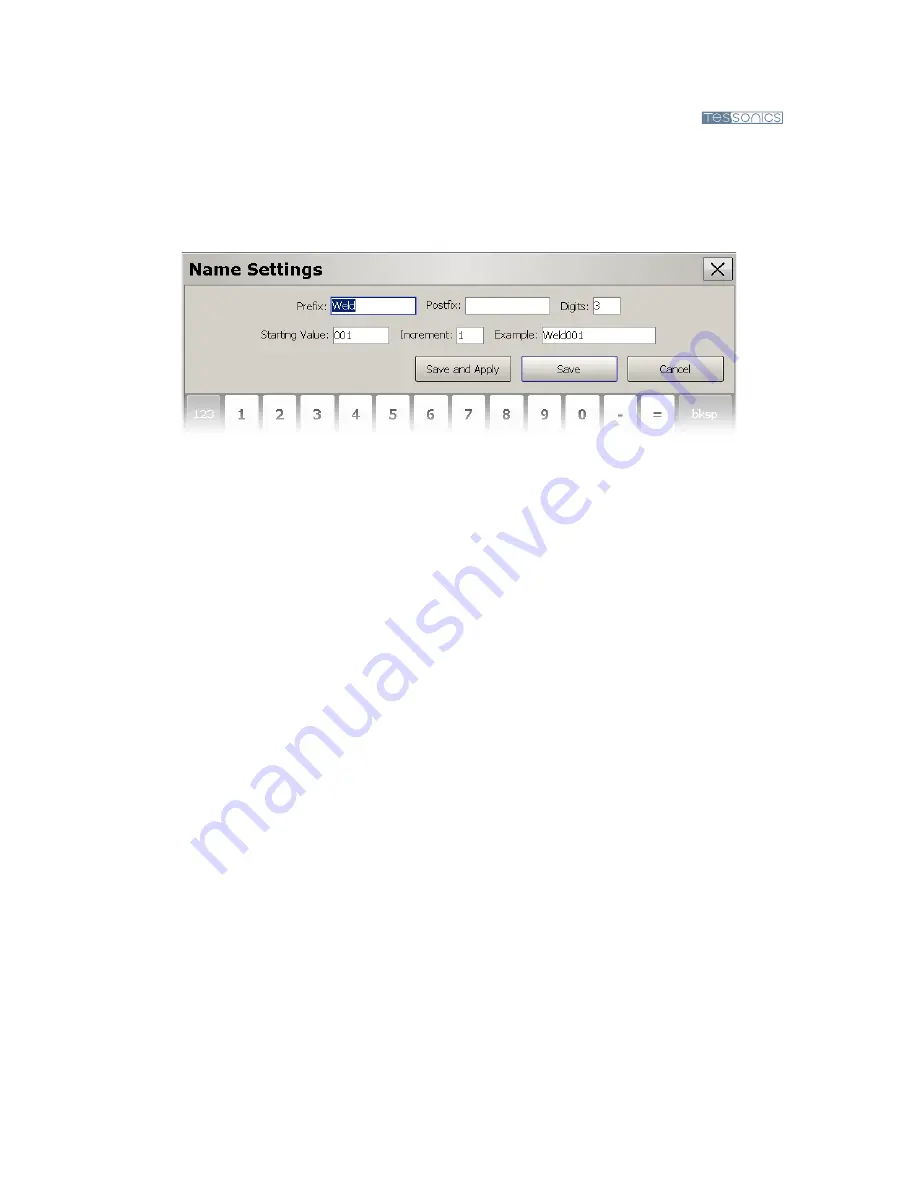

Figure 5.9

Weld name Auto-Generator window

First choose Name Settings from the pop-up menu instead of Rename. Doing so will launch

the window shown in Figure 5.9. is window allows you to customize the prefix, postfix,

number of digits, starting value, and increment. It also provides and example of what the

resulting name will look like. To save the changes the user must click either the Save or Save

& Apply button. Clicking save will apply the changes to all future welds; clicking Save &

Apply will apply the changes to all existing and future welds.

5.10.2 Part Inspection

e Part Inspection type is an advanced inspection type that uses Administrator defined

factory information. All of the factory information is stored in the RSWA and used by the

RSWA to guide and organize an inspection. It’s purpose is to help take care of the organiza-

tional work of the Inspector, so the Inspector can focus on checking welds. All of the factory

data is created using the Template Designer application, and then imported into an RSWA

via the RSWA Synchronizer program.

A screen shot of a Part Inspection can be seen in Figure 5.10.

Similar to a Custom Inspection, you can check welds and pass or fail them as you go along.

Unlike a Custom Inspection, you follow a predetermined list of welds that an Administrator

has created for you. ey are already named and ordered, and all that needs to be done is to

check the welds.

Содержание RSWA

Страница 1: ...RSWA Resistance Spot Weld Analyzer User s Guide 2008 02 05...

Страница 2: ......

Страница 4: ......

Страница 8: ...2 RSWA User s Guide...

Страница 24: ...18 RSWA User s Guide...

Страница 32: ...26 RSWA User s Guide...

Страница 53: ...47...