Tilt-Up Cab

The ROPS/FOPS approved cab (A) tilts up to allow

easier access while performing maintenance. It fea-

tures a gas spring assist and a brace mechanism to

hold it in place while tilted.

To tilt the cab:

1.

Remove any attachments that may be fastened to

the machine.

2.

(Optional) Raise the lift arms and secure them with

the lift arm brace. (See page 4-1.)

3.

Remove the two bolts that fasten the cab to the

chassis. They are located inside the cab, one in

each of the front corners.

4.

Once the bolts have been removed, tilt the cab

slowly upwards. The cab brace (B) should fall

onto the shoulder bolt (C) locking the cab in its

upright position.

The cab is now secure.

To lower the cab:

1.

Raise the cab brace so that the locking channel is

clear of the shoulder bolt.

2.

Hold the brace upwards and lower the cab until the

locking channel is clear of the shoulder bolt then

release the brace.

3.

The cab is now free to be lowered into operating

position.

4.

Lower the cab completely and then fasten it to the

chassis with the two bolts removed previously.

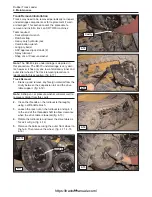

Jacking Procedure

Occasionally, your machine may need to be suspend-

ed off of the ground to perform maintenance. Exercise

caution when jacking the machine. Always use a jack

that is capable of lifting the machine and support its

weight with ASV approved jack stands while suspend-

ed. Never work on or under a machine supported only

by a jack.

To safely jack your machine:

1.

Remove any attachments that may be fastened to

the machine and raise the lift arms.

2.

Install the lift arm brace as instructed on page 4-1.

3.

Once the lift arms are secured, carefully exit the

machine.

4.

Roll or slide your jack under the front of the

machine and center the lifting pad directly under

the middle of the front torsion axle.

5.

Once in place, jack the machine upward making

sure it remains stable until it has reached sufficient

height to install an ASV jack stand beneath the

machine. (fig. 4-4)

6.

Slide the jack stand into place making sure it is

centered under the machine (left to right when

viewed from the front) and far enough back for the

machine to remain stable when the jack is lowered

and the front of the machine rests on the stand.

(fig. 4-5)

7.

Once the stand is in place, slowly lower the

machine onto the stand and then remove the jack.

Repeat steps 4-7 at the rear of the machine should

both ends of the machine need to be off of the ground

for service.

4-2

Rubber Track Loader

4. Maintenance

B

C

4-3

4-4

4-5

A

https://tractormanualz.com/

Содержание ASV SR70

Страница 5: ...IV https tractormanualz com...

Страница 11: ...1 6 https tractormanualz com...

Страница 41: ...4 20 https tractormanualz com...

Страница 87: ...12 8 https tractormanualz com...

Страница 105: ...14 6 https tractormanualz com...

Страница 109: ...15 4 https tractormanualz com...

Страница 125: ...16 16 https tractormanualz com...

Страница 133: ...17 8 https tractormanualz com...

Страница 137: ...18 4 https tractormanualz com...

Страница 139: ...19 2 https tractormanualz com...