MAINTENANCE

3Ć31

186 MM159 (6–94)

DEBRIS HOPPER AND DUST FILTER

DEBRIS HOPPER

The debris hopper collects debris swept up by the

machine. It should be emptied after every work

shift. The debris hopper floor clearance should be

checked after every 50 hours of operation. The

filter assembly to hopper seal can also be

adjusted to correct dusting when shaking the dust

filter.

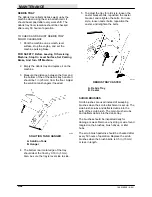

TO CHECK AND ADJUST HOPPER FLOOR

CLEARANCE

1. Park the machine on a smooth, level surface

and set the machine parking brake.

2. Stop the engine.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine.

3. Empty the debris hopper and replace it on

the machine.

4. The bottom rear metal edge of the hopper

should clear the floor by 0.5 in (15 mm).

Also, be sure the hopper is level side to

side.

5. To adjust the hopper, loosen the hanger

bracket bolts, reposition the hanger bracket,

and retighten the hanger bracket bolts. Be

sure the hopper brackets do not rub against

the pivot pins preventing the hopper from

floating.

B

A

03159

HOPPER HANGER BRACKET

A. Hopper

B. Hanger Bracket

Содержание 186

Страница 1: ...186 MM159 Rev 05 12 95 Operator Manual ...

Страница 10: ...SPECIFICATIONS 186 MM159 6 94 1Ć2 ...

Страница 14: ...OPERATION 186 MM159 6 94 2Ć2 ...

Страница 52: ...MAINTENANCE 186 MM159 6 94 3Ć16 ELECTRICAL SCHEMATIC For machines below serial number 003181 03145 ...

Страница 53: ...MAINTENANCE 3Ć17 186 MM159 6 94 ELECTRICAL SCHEMATIC For machines serial number 003181 to 004368 03145 ...

Страница 54: ...MAINTENANCE 186 MM159 6 94 3Ć18 ELECTRICAL SCHEMATIC For machines serial number 004369 and above 03145 ...

Страница 84: ...MAINTENANCE 186 MM159 6 94 3Ć48 ...

Страница 86: ...APPENDIX 186 MM159 6 94 4Ć2 ...

Страница 88: ...APPENDIX 186 MM159 6 94 4Ć4 ...