- 3 -

3. WIRING

3.1 General

Electrical power wiring must be fitted and certified by

persons with appropriate qualifications and certification.

A signed 'Certificate of Compliance' must be left with the

unit for insurance purposes.

3.2 Power to unit

All power wiring is to be done to the appropriate electrical

standard of the country in which the unit is being installed.

The person installing the wiring is responsible for the

correct selection of wiring size and auxiliary components.

See the Specification Sheet for supply voltage range,

frequency, phase and maximum operating current .

Wire the unit directly from the Electrical Distribution

Board.

The unit should have its own dedicated circuit breaker

on the Distribution Board.

Route the power supply cord

through the entry hole provided.

MWH/R 900: Use the mounting track provided, which

includes cable ties.

DO NOT install wiring in contact with refrigeration piping.

Refer Figure 3 for client wiring.

3.3 Power to optional Room AC Units – ducted type

Single phase mains power wiring to each zoned unit (if

applicable) shall be taken from the distribution board.

3.4 Control

Simply connect power (and water) and switch the unit ON

and the unit's built-in UC8 Controller works to maintain

the default leaving water temperature (LWT) of 45°C.

The maximum LWT can be raised to a maximum of 55°C

if the application requires it, eg long pipe systems and/or

multiple small fan coil units or radiators.

Note: Higher LWT will reduce the efficiency of the unit.

To adjust the supply water temperature, refer

Commissioning 4.3.

MWR only:

In cooling mode, the UC8 works to maintain the default

leaving water temperature (LWT) of 7°C. The minimum

LWT can be lowered to a minimum of 3°C if the

application requires it.

Note: Lower LWT will reduce the efficiency of the unit.

Adding glycol to the water loop is recommended for low

LWT applications.

A single load Leaving Air Temperature (LAT) control

application requires a Programmed Logic Controller

(PLC) to be installed. Refer Temperzone for

'LAT Control

User Guide' for set-up.

MWH 900/2000 models include a PLC for stage control

of more than one compressor, and de-ice control

management.

3.5 BMS Control

MWH/R external control options are limited to Remote

On/Off and Modbus/RTU control using the on-board UC8

(refer Appendix I).

MWH/R 250, 450 Single Compressor models:

An optional PLC is available to enable more options

including BACnet and scheduling. Refer to Temperzone

for more information.

MWH 900/2000 Multiple Compressor models:

PLC supplied as standard and includes BACnet and

scheduling. Refer to Temperzone for more information.

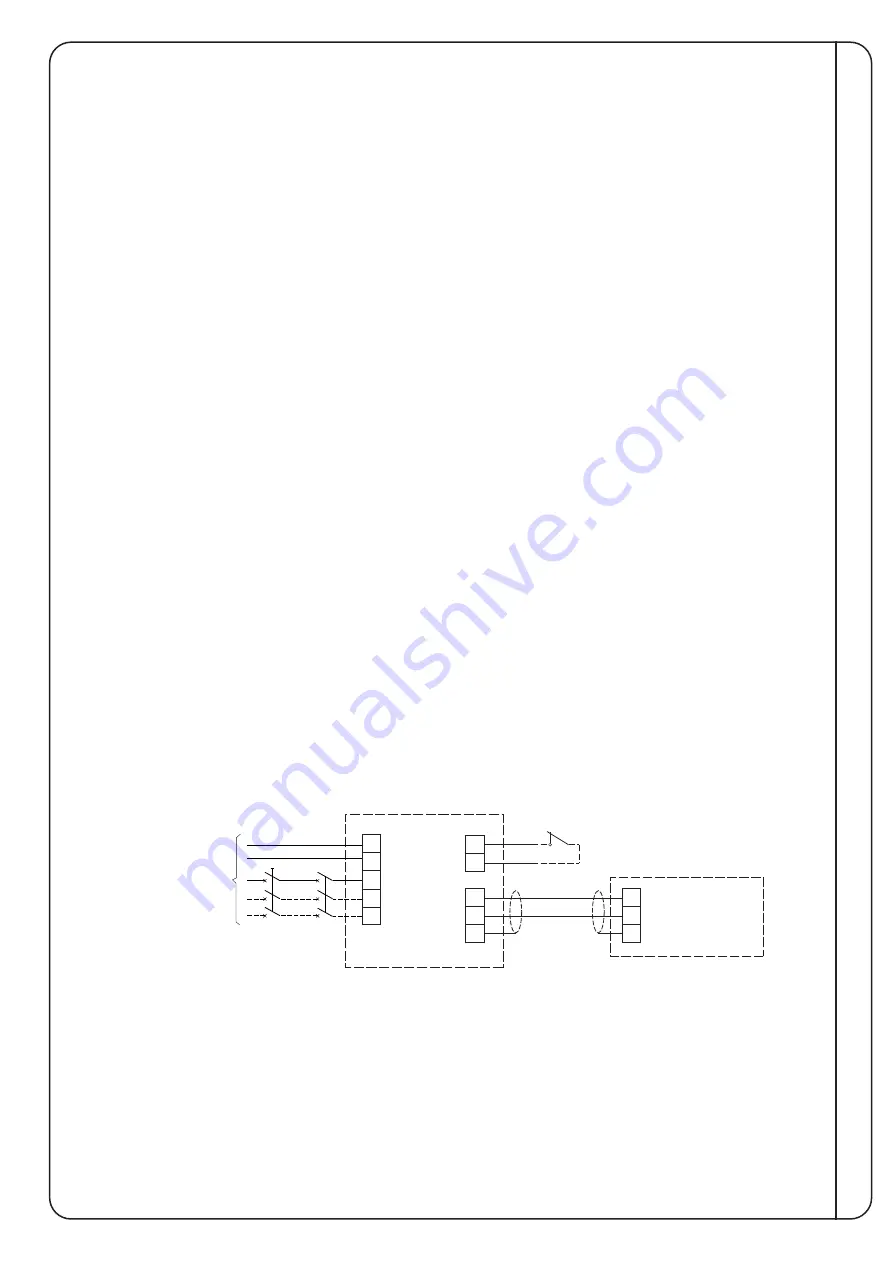

WIRING

Figure 3 Client Wiring

MWH/R Unit

UC8

UC8

E

N

L1

L2

L3

Power Supply

1Ø (2 core+E)

or

3Ø (4 core+E)

depending on unit

External

Protection

Isolator

On

0V

Optional

Remote On/Off

(remove link if used)

Optional

Communicating

BMS Controller

Modbus RTU

B1

A1

0V

B

A

REF

Control

- shielded

twisted pair

2 core + screen

link