5–6 Auto-Tune

The auto-tuning process is performed at the set point. The process will oscillate around the set point during the

auto-tuning process. Set the set point to a lower value if overshooting beyond the normal process value would be likely

to cause damage.

The auto-tune program should be applied:

• During initial set-up

• When the set point is changed substantially from the previous auto-tune

• When the control results are unsatisfactory

When preparing to run the auto-tune program:

• Make sure that all parameters are configured correctly.

• Make sure that PB is not set to zero, because the auto-tune program cannot be run in on-off control mode.

• Set the set point at the normal operating process value (or at a lower value if overshoot is likely to cause damage) and

use normal load conditions.

• Press and hold the up and down keys for 3.2 seconds then release together. The upper display will flash while the

auto-tune program is running.

Auto-tune “teaches” the controller the main characteristics of the process. It “learns” by cycling the output on and off.

The results are measured and used to calculate the optimum PID values for the process which are then automatically

entered into the nonvolatile memory.

During the second period of the auto-tune program, the controller performs PID control to verify the results, and an

OFST value is obtained and entered in the memory.

To stop the auto-tune program, press the up and down keys and release them together. The upper display will stop

flashing, indicating that the auto-tune program has been aborted. Once the controller has entered the verifying period,

auto-tuning cannot be stopped.

5–7 Tuning the Controller Manually

• Make sure that all parameters are configured correctly.

• Set PB to zero. Set HYST to minimum (0.1°F or 0°C).

• Set the set point at the normal operating process value (or at a lower value if overshoot is likely to cause damage) and

use normal load conditions.

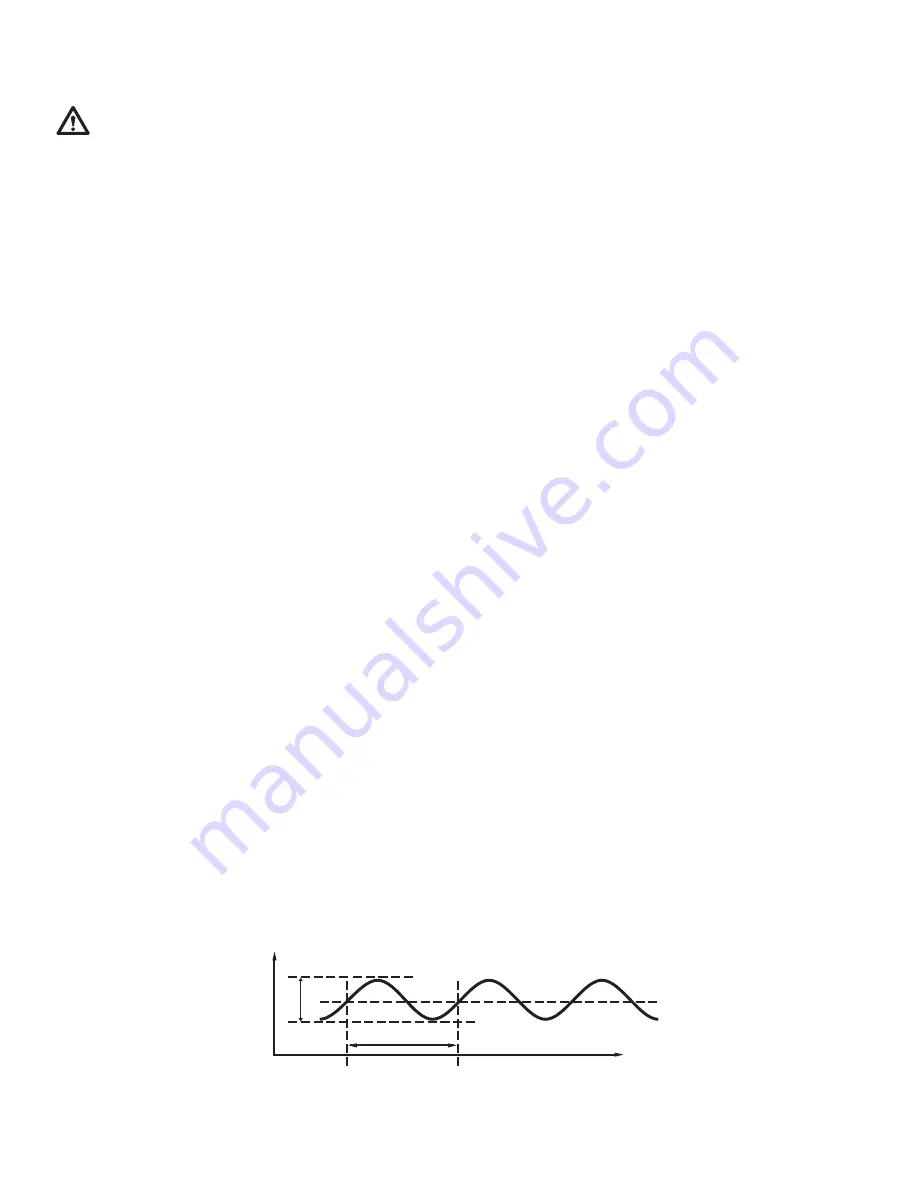

• Switch on the power supply to the heater. Under these conditions, the process value will oscillate about the set point

and the following parameters should be noted:

1. The peak to peak variation (P) of the first cycle in °F or °C (i.e., the difference between the highest value of the first

overshoot and the lowest value of the first undershoot).

2. The cycle time (T) of the oscillation in seconds (see figure below).

The control setting should then be adjusted as follows:

PB=P (°F or °C)

TI=T (seconds)

TD=T/4 (seconds)

16

SV

T

PV

Time

P