CTD-ES and CTD-ER Technical Manual

page 44

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Do NOT use high pressure or you may damage softer surfaces.

Always dry the system before placing it in the storage case to avoid fungus or mold growth.

After cleaning the instrument, check it carefully for signs of damage. Check the bulkhead con-

nector for looseness or other signs of damage. Check the pins of the bulkhead connector. They

should be kept clean at all times. Clean the connector pins and sockets with an alcohol wipe,

and when reconnecting, lubricate the rubber portion of the pins with an O-ring quality silicone

based lubricant.

Oil Fill Procedure and Capillary Tube Installation

The pressure sensor used in your instrument is exposed to ambient pressure through a pressure

port and an oil-filled capillary. The oil provides the required pressure coupling and is an electri-

cal insulator that prevents corrosion due to the dissimilar material compositions of the trans-

ducer and instrument housing.

Included with your instrument is a capillary tube installation kit. The following procedure will

provide guidance to allow you to install the capillary onto the instrument.

Should you require further assistance please do not hesitate to contact Teledyne RD Instru-

ments and ask to speak to a customer service representative.

The following parts should be included in your kit:

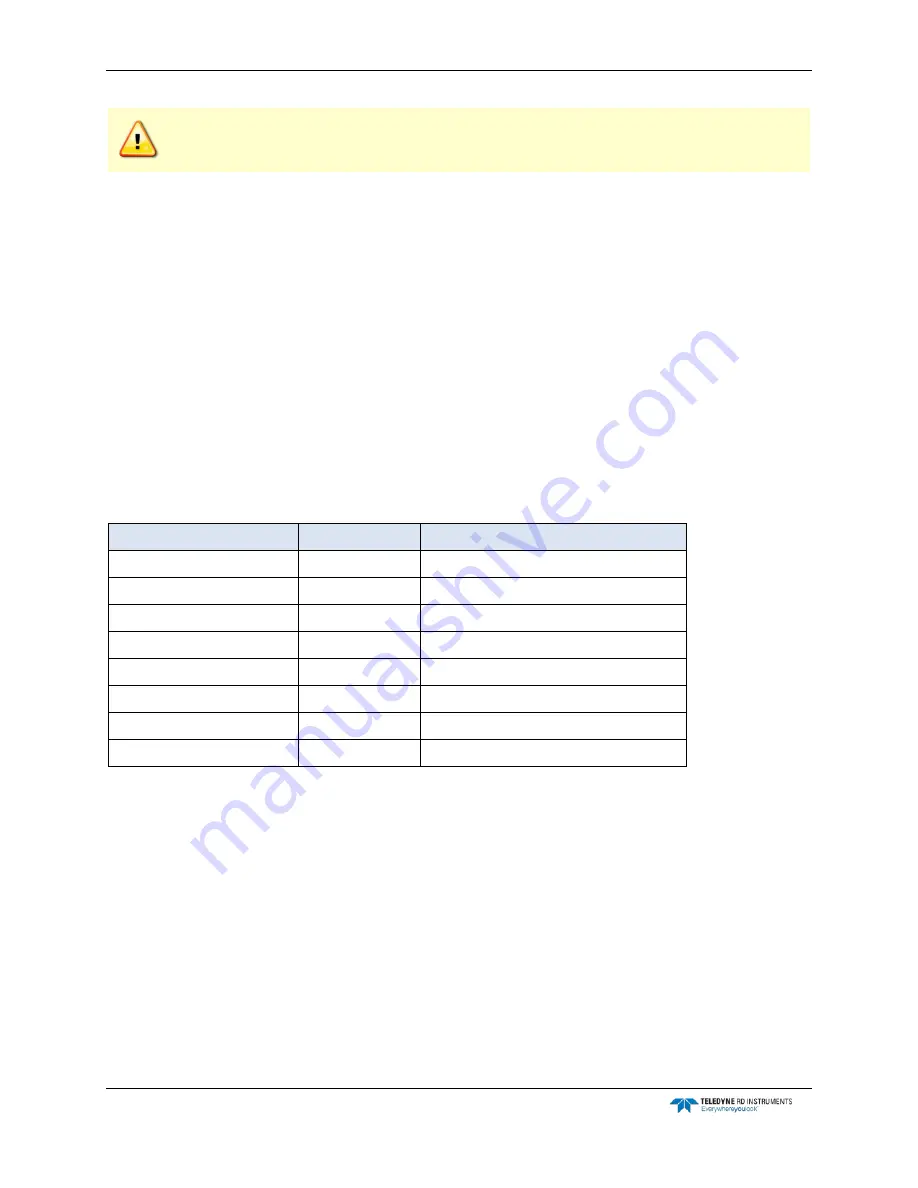

Part Number

Quantity

Description

1400-65361

1

Nalgene Bottle

5400-7510A653

1

Syringe

5400-TS19X1

1

Needle

NY-200-1-2ST

1

Capillary Body Assembly

A150-045

1

Capillary Tube

1605-378372

1 ounce

Oil, Dow Corning 200 CTS

97F-6003-00

1

Needle Cover

AN2005001

1

Oil Fill Procedure

Should you require additional parts from this kit please contact a Teledyne RD Instruments

sales representative. Please have the part number on hand to acquire price and delivery infor-

mation.