7

ITEM

DESCRIPTION

ITEM

DESCRIPTION

17

Flow

Control,

Main

Cylinder

21

Air

Filter

18

Flow

Control,

Injection

Rod

22

Wrench

19

Voltage

Select

Switch

23

Accessories

Bracket

20

Power

Input

Socket

with

Fuse

box

24

Cartridge

Holder

Bracket

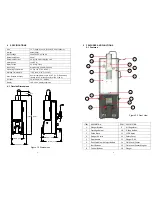

Figure 4.0 Partial Side View

Figure 3. Back View

24

23

22

21

17

18

19

20

8

Figure 5.0 Buttons and Screen Identification

MIX CYCLE

SET

PROGRAM #

MODE

PRESSURE

TOTAL MIX

TIME

SAFE TO

RUN

POWER/

(-) CYCLE

BUTTON

MODE/

(+) CYCLE

BUTTON

SETUP/

SAVE

BUTTON

CYCLE

COUNTER

Figure 6.0 Setup Screen Identification

PROGRAM #

MODE

PRESSURE

MIX CYCLE

SET

CYCLE

COUNTER

TOTAL MIX

TIME

DELAY TIME AT UP

STROKE