11

6 SETUP

AND

OPERATION

NOTE: To ensure proper voltage setting, units shipped from the

factory will not have the fuse installed. Refer to Section 6.1 to

install proper fuse and select proper voltage.

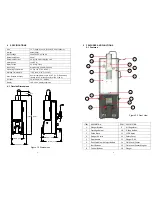

6.1 Fuse Installation/Voltage Selection

1. Remove the fuse holder by using a flat head screw driver to

pry it open.

2. Insert proper fuse into the fuse box, refer to table below

3. Re-install the fuse holder into the unit

4. Select the proper voltage by sliding the voltage switch up or

down.

Voltage Range

Voltage Setting

Fuse Rating

100V – 120V

115V

2 Amp, Type F

220V – 240V

230V

1 Amp, Type F

Figure 7.0 Fuse Installation

Voltage

Selector

Switch

Fuse

Holder

Screw

Driver

Fuse Holder

with Fuse

installed

Fuse

Fuse Holder

12

6.2 Turn On the Unit

1. Insert the power cord to the power socket (Fig. 3, 20).

Caution: Make sure the proper fuse has been installed

and correct voltage has been set. Refer to section 6.1

for instructions.

2. Connect the air filter assembly to the air inlet (Fig. 3, 21).

3. Connect the air hose to the air filter assembly

Caution: The air filter assembly (7091-9080), supplied

with the unit, must be installed to ensure proper air

filtration.

4. Set the air Pressure to 80 psi (5.5 bars) minimum

•

Rotate the Air Pressure regulator knob (Fig. 1, 9)

clockwise to increase the Air Pressure.

•

Rotate the Air Pressure regulator knob counterclockwise

to decrease the Air Pressure.

5. The desired Air Pressure will be displayed on the screen.

6. Turn on the unit by pressing the power button (Fig. 5). The

cartridge holder should move up to home position. If it does

not move up, please check pressure connection.

Power Cord

Air Filter

Figure 8.0 Air and Power Connection