23

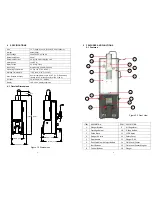

Figure 18.0 Inside Assembly Level One

ITEM PART

NUMBER

DESCRIPTION

QTY

36 2900-0015

LCD

1

38

7091-9000

PCBA, TECHKIT MIXER

1

ITEM PART

NUMBER

DESCRIPTION

QTY

39

535

PLUNGER AIR INLET

1

40

5500-0008

FLUID LEVEL SENSOR

1

41

3300-0408

TUBE HOLDER, ¼” TUBE DIA.

1

42

7091-9140

MAIN AIR CYLINDER

1

43

5100-0060

VOLTAGE SELECT SWITCH

1

44 2100-0372

POWER

CONNECTOR

1

Figure 19.0 Inside Front Cover Assembly

24

Figure 19.0 Inside Assembly Level 2

ITEM PART

NUMBER

DESCRIPTION

QTY

45 TSD650-21

SOLENOID

VALVE

2

46

2600-0132

SOLENOID VALVE, 4-WAY

1

47

1700-0027

DC POWER SUPPLY

1

48

7091-9150

AIR CYLINER, INJECTION ROD

1

49 TSD210-6

FLOW

CONTROL

1

50

7091-9130

SPINDLE SHAFT ASSY /BEARING SLEEVE

1

51 7091-9160

MOTOR

ASSEMBLY

1

52

2700-0046

FILTER, EMI, 115/250 VAC, 3A, 50-60 Hz

2

53 7091-9120

MOTOR

DRIVER

1