7

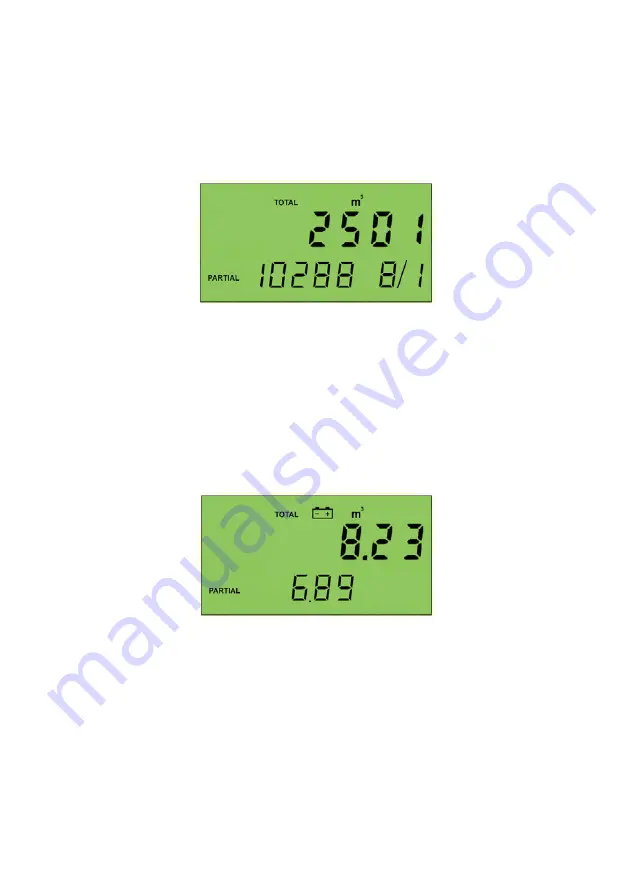

4.3 Counter

overflow

If one of the counters overflow, this condition is indicated at the right of the partial totalizer. If

none of the counters has overflowed then this part of the display is blank. When one of the

counters overflows then the display will show “A/B”, where “A” is the number of times that

the partial counter has overflowed and “B” is the number of times the total counter has

overflowed. The digit that indicates the number of times the counter has overflowed can be

effectively placed in front of the digits of the counter to give an extra digit. If a counter

overflows more than 9 times then the digit will be shown as “X”.

If the partial counter overflows and the total counter does not, and then the partial counter is

reset, the display will then go blank again. The overflow indication of the partial counter is

reset when this counter is reset.

In the above screen the total counter is shown as having overflowed once (this would be

equivalent to a count of 10002501) and the partial counter as having overflowed eight times

(this would be equivalent to a count of 810288).

5 MAINTENANCE

The battery has a life time of about 5 years. When the instrument detects that the battery

should be replaced, it shows a battery icon on the screen.

To change the battery, the plastic front cover must be removed. Then the battery, that is

situated below the push buttons, can be replaced.

After replacing the battery, it is not necessary to reprogram the pulse per litre factor of the

meter.

CR2450 batteries are easily found in the shops. If you prefer, we can change it in our factory.

6

EXAMPLE OF USEFUL CALCULATIONS

6.1

Measurement error correction

The calibration of the mechanical flowmeters is made with water at 20ºC. If a liquid of other

characteristics from the above specified is used, or for reasons of turbulences in the flow,

measurement errors can be induced.