408-35043

Rev

D

16

of 30

5.3.

Adjusting the insulation crimp

The insulation crimp is adjustable in increments of 0.19 mm [.0075 in.]. Pull the insulation crimp dial out (refer

to Figure 5) and turn it to line up with a number (1 through 18) so that it is shown at the indicator notch on the

ram.

Number 1 makes the loosest crimp.

Number 18 makes the tightest crimp.

The total range of adjustment is approximately 3.30 mm [.130 in.]. Start with number 1 and make test crimps

while increasing the setting one number at a time until the proper insulation crimp height is achieved.

NOTE

Some applicators have a special insulation adjustment dial with different range and increments. Refer to the marking on the

front of the insulation crimp dial for correct increments.

5.4.

Adjusting the terminal strip feed

Mechanical feed applicator

NOTE

When adjusting a mechanical feed applicator, always start by properly adjusting the stroke length. Then adjust the fine feed

adjustment to position the terminal over the anvil.

1. With the terminal strip properly loaded, check the position of the lead terminal relative to the slug blade.

Position the feed pawl in the required location on the terminal (typically the end of the wire barrel).

Refer to Figure 6. The slug blade must remove the connecting tab between lead and second terminals

without deforming either terminal.

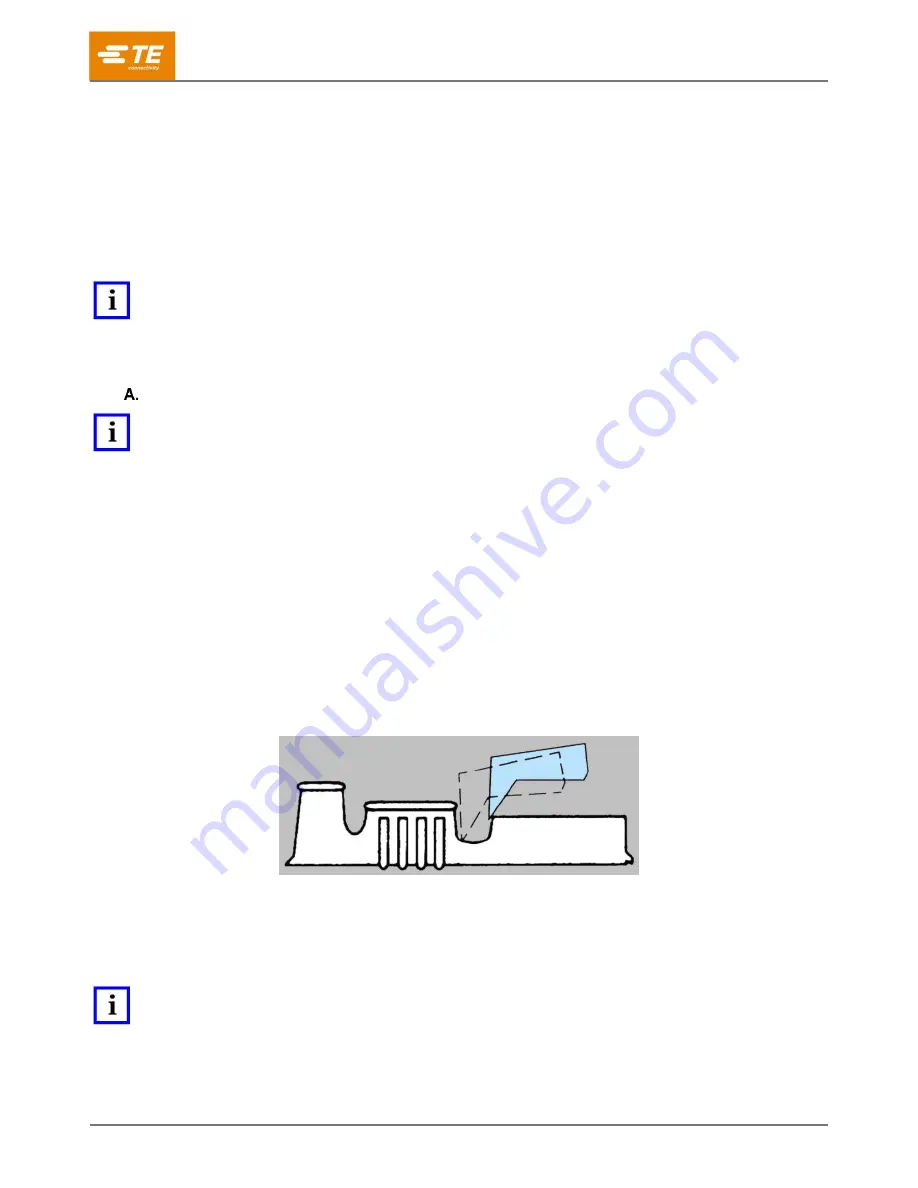

2. Watch the feed pawl as the machine is hand-cycled (or slowly cycled) several times. It should have

enough over-travel on the backstroke to pick up the next terminal, but not so much over-travel that the

feed pawl moves up onto the body of the terminal (see Figure 16).

If the pick-up point is the mating end of the terminal, the backstroke over-travel should be about

equal to the distance between the wire barrel and the mating end of the terminal (Figure 2).

For other types of terminals (for example, ring tongue), over-travel should be about the same,

depending on the terminal features and configurations (for example, stud hole).

Figure 16: Feed pawl backstroke over-travel

3. Check the backstroke position.

If the backstroke position is correct, the tab is correctly slugged out, and the terminals are not

damaged, the feed adjustments are complete.

If not, continue to the next step.

NOTE

Two adjustments work in combination to properly position the lead terminal over the anvil and give the proper backstroke

position to pick up the next terminal feed hole. Use

one

or

both

adjustment types to properly adjust the applicator.