6.2.3 STOW FEATURE

The STOW position needs to be programmed during installation. The monitor needs to “find” two (2) hard stops, one for each axis,

before the monitor can move to the STOW position. When programming, the first two commands teach the monitor where to find the

hard stops. This guarantees that the position is accurate. From that point, the operator can program the move to the final STOW

position.

During normal operation, each time the STOW button is pressed, the monitor moves the nozzle to the full straight stream position,

moves to each programmed hard stop, and then moves to the STOW position. While the monitor is performing the STOW feature,

pressing any button will stop the monitor.

6.2.3.1 PROGRAMMING

STOW programming must be initiated within 1 minute of applying power to monitor. After 1 minute, programming access is blocked.

Power must then be cycled to reset 1 minute timer.

Press & hold STOW button (~10 seconds) until LED blinks. Release button. LED will continue to blink while in program mode.

Press & release LEFT/RIGHT or UP/DOWN button of axis that will move to first hard stop. LED will blink rapidly when hard stop is

reached.

Press & release LEFT/RIGHT or UP/DOWN button of axis that will move to second hard stop. LED will blink rapidly when hard stop is

reached.

Use LEFT/RIGHT or UP/DOWN buttons to move monitor to first point of stow routine, press & release STOW button. LED will blink

rapidly to acknowledge position.

Repeat until pattern is complete (up to 10 points).

Press & hold STOW button until LED turns off. Release button.

FIRST AXIS TO MOVE:

SECOND AXIS TO MOVE:

MOVE TO STOW POSITION:

6.2.3.2 STOW PROGRAMMING EXAMPLE

- Press & hold STOW button until LED blinks.

- Press & release UP button, monitor will move until hard stop reached. LED blinks rapidly.

- Press & release RIGHT button, monitor will move until hard stop reached. LED blinks rapidly.

- Press LEFT button to move 45 degrees, Press & release STOW button. LED blinks rapidly.

- Press DOWN button to move 90 degrees, Press & release STOW button. LED blinks rapidly.

- Press & hold STOW button until LED turns off.

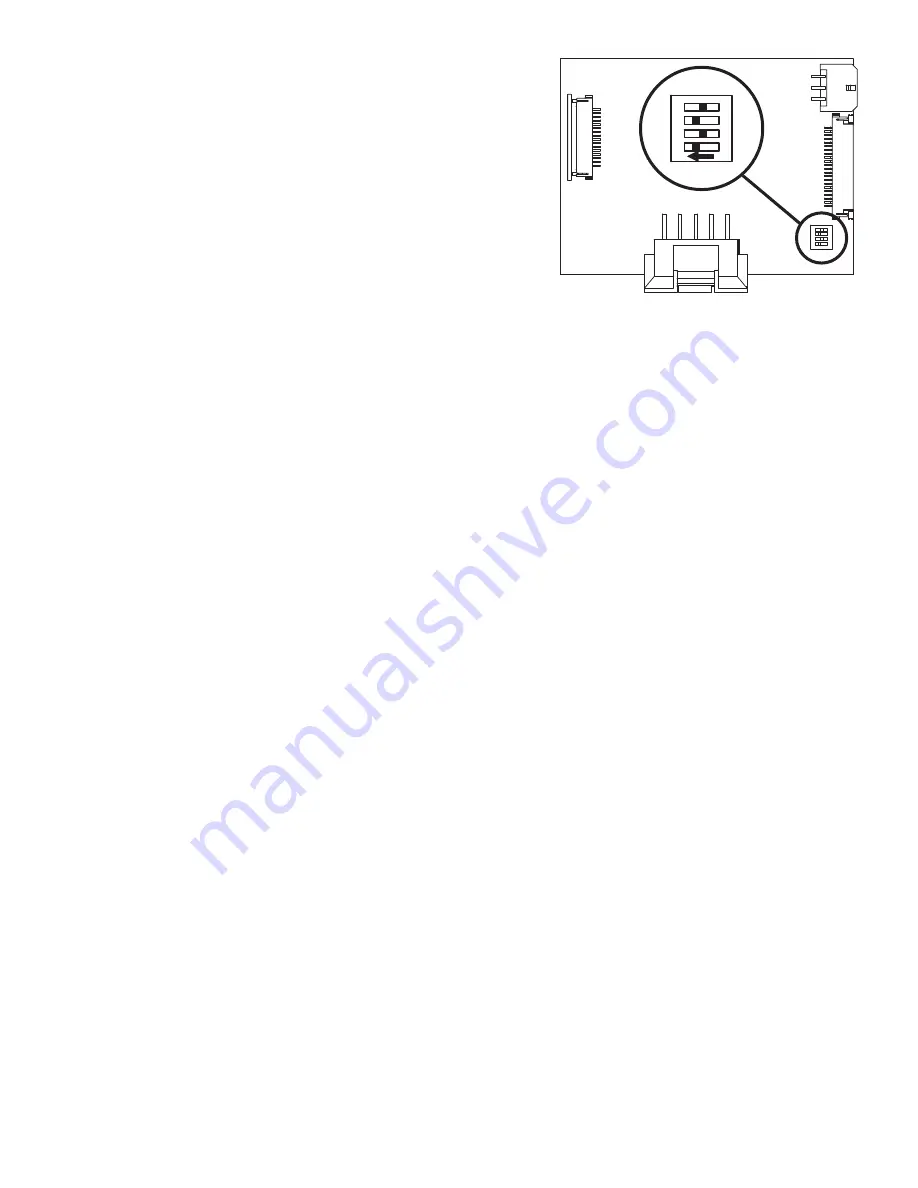

6.2.2 MASTER OVERRIDE FEATURE (DIP #1)

Any operator station with a communication board can be

reconfigured with the master override feature. These stations

include the Y4E-RP, Y4E-RO, Y4E-CT-30, Y4E-CT-100,

Y4E-TS, or any inputs connected to an Y4E-COMM. To

enable the master override feature on an operator station,

follow these steps:

1. Remove lid from enclosure.

2. Locate DIP switches on communication board.

3. Slide DIP switch #1 to the ON position.

4. Replace lid. Verify rubber seal is clean and undamaged.

Verify that no wires are caught between lid and box.

Figure 6.2.2

Master Override Setup

ON

CTS

12

3

4

21

6.2.4 OSCILLATE FEATURE

The OSCILLATE feature allows the user to program a repeating pattern to control the horizontal and vertical axes of the monitor. While

in the OSCILLATE pattern, the monitor will pause while the user changes the stream pattern. Pressing any other button will stop the

OSCILLATE pattern.

A label is supplied with each operator station that can be mounted on or near the station as a reminder of how to program the

OSCILLATE pattern. The OSCILLATE pattern needs to be programmed before use. The pattern will be cleared each time power is

cycled to the monitor. For fixed monitors, the monitor may be configured to store the program permanently. See Section 6.2.4.2.