CNC-210A Series H6681 User manual

Page

6

of

20

έᚊཝҋજ̼ѣࢨ̳Φ

TAILY AUTOMATION CO.,LTD.

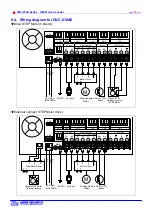

4.3. Guiding traverse shaft introduce setting

During set the

『

SHIFT

』

,

『

WIDTH

』

and

『

guiding traverse travel limit

』

, can use numeric keypad

to set location data or can also use

,

keys to leading the guiding traverse shaft location.

4.4. Clear all winding parameter

In the READY mode, press

will clear all the winding parameter in the memory. Be

cautious in using this function or all the data will be lost.

5. WINDING METHOD DESCRIPTION

Prior to winding, the general winding principles are explained below so the operators can have a

better understanding of the performance of the controller and make better use of it.

5.1. Counting

mode

Absolute counting mode

Winding spindle shaft is capable of fixed-point stopping. Upon each restart, the turn count will

reset only the integer portion of the turn’s to zero, with the decimal unchanged. For example,

for a previous number of 100.3 turns, when restarting the next step winding,

the counting will

start with 0.3 to avoid accumulation of spindle shaft free play error from consecutive windings.

This counting method may cause insufficient winding by one turn. Therefore, when starting

from

0

.

9

, the spindle will turn to the

0

.

0

before it starts counting.

Relative counting mode

This counting method zeros the counter upon each restart, therefore it is easy to understand

and will not cause insufficient winding.

5.2. Wire-guiding

mode

Interlace wire-guiding

If the

『

WIDTH

』

of the step is zero, the wire-guiding becomes interlace mode. When it begins

winding, the wire-guiding will follow the wire direction to proceed two wire diameters and

regress one wire diameters cyclically until the step of winding ends. This mode especially suits

the inductor winding.

Non wire-guiding

Sometimes, the winding device may be used to winding adhesive tapes or copper foil. When

the wire-guiding is not needed,

『

PITCH

』

may be adjusted to zero and the wire-guiding won't

be move.

5.3. Operation

mode

Single click mode

When press the start switch, the motor start winding, and when you release the start switch,

the motor stop winding immediately.

Double click mode

When press the start switch, the motor start winding, and if you want to pause the motor, you

have to release the start switch then press it again.