CNC-210A Series H6681 User manual

Page

2

of

20

έᚊཝҋજ̼ѣࢨ̳Φ

TAILY AUTOMATION CO.,LTD.

1. INTRODUCTION

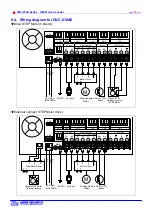

CNC-210A is a series of COIL WINDING MACHINE CONTROLLER developed by

TAILY

AUTOMATION

. It not only retains all the features of previous designs, it also has a low noise

level and is less sensitive to external power fluctuation. Furthermore, it also includes a RS-485

network interface, making coil-winding operation easier to manage.

CNC-210A also features an integrated design: putting stepper motor driver, DC motor speed

controller, brake and power supplier control circuits into one control box, simultaneously

achieving size reduction, high performance and low cost.

CNC-210A Series offers CNC-210AS “Standard Model” and CNC-210AE "External Connection

Model”, depending on whether a close-loop driver is provided for various applications.

MODEL

Winding Spindle

Guiding Traverse

CNC-210AS

Drive 0.5hp DC motor in directly.

Drive two phases 2A STEP motor in

directly.

CNC-210AE

External connect winding spindles

motor driver.

Drive two phases 2A stepper motor in

directly,

Or external connect guiding traverse STEP

motor driver.

2. MAIN

FEATURES

Single chip Microprocessor design,

has further higher performance and higher functions; it

also has less sensitive to external power fluctuation or to external electromagnetic

interference.

Memory use FLASH ROM, capacity

capable storing up to 1000 steps winding data, 9 winding

parameters, and 5 options can be independently assigned for each step. Off-power memory

retention without battery.

Winding speed can be specified using the front panel keypad, resulting in easy programming

of multi-step, multi-speed settings.

Guiding traverse shaft stepper motor with a constant-current driver offering fast wire guiding

speeds.

Guiding traverse shaft offering 10 steps moving speed selection.

Offering RS-485 interface for PC linking and data transfer.

Software can be update through the personal computer.

Power input AC100V~120V

、

220V~240V 600VA(max).