1

In order to ensure that the pump will be operated correctly and safely, this OPERATION MANUAL contains some

guidelines for the user in the form of important safety precautions and considerations which, depending on their

seriousness, are categorized as set forth below. Be absolutely sure to heed these precautions and considerations.

!

WARNING

• This is used to indicate a condition or action which may result in death or serious injury if the instructions given

are ignored and the operations are performed incorrectly.

!

CAUTION

• This is used to indicate a condition or action which may result in injury and/or damage to personal property if

the instructions given are ignored and the operations are performed incorrectly.

IMPORTANT

• This is used to indicate a condition or action which must be established or carried out in order to maintain the

performance and service life of the equipment.

NOTE

• This is used to indicate supplementary information.

Conditions of Use

!

WARNING

• This pump cannot be used in explosion-proof regions or in explosive or combustible atmospheres.

!

CAUTION

• This pump must be used for the purpose of transferring or injecting liquids only. Using it for any other purpose may

result in accidents and/or malfunctions.

• This pump cannot be used to transfer or inject any liquids containing slurry.

• This pump’s discharge volume cannot be adjusted by operating the valve on its discharge pipe.

• The characteristics of this pump are such that pulsation will arise. If pulsation threatens to be a problem, install an

air chamber or some other device for reducing the effects of pulsation.

• Do not use the pump outside the following usage ranges. Doing so may cause malfunctions.

How to operate the pump safely

Ambient temperature

0 to 40 °C*

Ambient humidity

35 to 85%RH

Temperature of liquid

0 to 40 °C (no freezing)

Viscosity of liquid

Less than 50 mPa • s

Altitude of installation location Less than 1,000 m

Environmental protection

IEC standard : IP65 or equivalent (Water - and dust - proof)

* Transport and store the pump at temperatures within the −10°C to +50°C range. Do not subject the pump to strong impacts.

✽

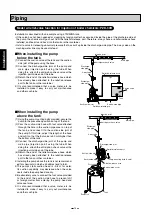

Install the tank at a position higher than the pump (so that the pipe is connected to force the chemical downward).

✽

The volume and viscosity of the liquids that can be pumped differ according to the conditions under which the pipes are

connected and the properties of the chemicals to be pumped.

Installation, Piping & Connections

!

WARNING

• This pump does not have explosion-proof specifications. Do not install it in explosion-proof regions or in explosive or combustible atmospheres.

• Install the pump in a location that cannot be accessed by anyone but control personnel.

!

CAUTION

• If this pump has been dropped or damaged, consult your vender or a TACMINA representative. Using a dropped or

damaged pump may result in accidents and/or malfunctions.

• Do not install the pump where there is a risk of flooding or where there are high levels of moisture or dust. Doing so

may cause electric shocks and/or malfunctions.

• This pump has a water-proof construction (equivalent to IP65 under IEC standards). However, it is made of plastic so make every attempt to

avoid installing it in a position that will shorten its service life (such as a position where it will be exposed to direct sunlight, wind or rain).

• Connect the pipes to the pump properly.

• Do not connect the pipes above a passageway. Do not install the pipes where the chemical may splash onto people

even if the hose/tube should break.

• When using a pump with a relief-valve function, always attach a hose for relief purposes, and lead the end of the

pipe back to a tank or other container.

01-08̲PZD総合取説̲E.indd 1

01-08̲PZD総合取説̲E.indd 1

2010/07/22 18:22:57

2010/07/22 18:22:57