27

Installation

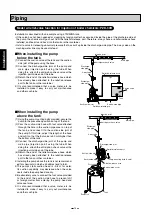

Suction-side joint

Cap nut

Cap nut

Discharge-side joint

PTFE tube

PTFE tube

Injection point

(Rc1/2)

Main pipe

Nozzle grip

■

PTFE tube

• When bending the tube, provide sufficient leeway

in the bending so that the tube will not break. Also

ensure that it will not be rubbed against or trodden on.

• Insert the tube firmly so that it will not become dis-

connected, and tighten the cap nuts securely. Do not

excessively tighten the cap nuts. Doing so may dam-

age or break the joint.

• If the temperature of a liquid or ambient temperature is

higher than room temperature, the tightening force will

be reduced, and the tube may become disconnected.

After operation has started, tighten up the cap nuts as

appropriate.

• When tightening the cap nuts, hold the tube to prevent

it from being twisted. The joints and other areas may

be loosened by the return force of the tube.

• The pump comes with a 3-meter long tube for both

the discharge side and suction side. When longer tube

is used, the pressure loss may exceed the pump’s

maximum discharge pressure so thicker tube will be

required. Provide details on the (1) viscosity of the liq-

uid, (2) length of the pipes (how they are positioned)

and (3) specific gravity of the liquid to a TACMINA rep-

resentative who will select the appropriate tube size.

• When disconnecting the tube for jobs such as main-

tenance and then afterwards re-connecting the same

tube, cut about 10 mm off the end of the tube before

re-using them.

Connecting

Model for injection of general chemicals (large type: STCT)

■

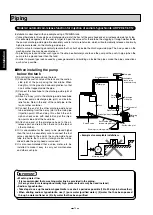

Anti-siphon check valve

This pump is provided with an anti-siphon check valve. Use this valve at the injection point unless there is a good rea-

son not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When a chemical greatly exceeding the pump’s rated discharge volume is being fed (prevention of overfeed)

✽

Even with a rising pipe, overfeed may occur if the pipe is too long.

(1) The anti-siphon check valve has an R1/2 external

thread. Provide an Rc1/2 internal thread at the injec-

tion point.

(2) Wind sealing tape around the external thread of the

anti-siphon check valve, and screw the valve into the

injection point.

✽

If it is hard to screw the valve in, grasp the nozzle

grip using a tool such as pliers, and tighten the

valve gently.

✽

When connecting the tube with the anti-siphon

check valve already mounted on it to the main

pipe, be absolutely sure to hold the valve body

and turn the cap nut. If the cap nut is turned with-

out holding the body, the threaded part on the

nozzle may be damaged.

09-32̲PZD総合取説̲E.indd 27

09-32̲PZD総合取説̲E.indd 27

2010/07/22 8:42:34

2010/07/22 8:42:34