Form 43343320

-20-

Aug 2012

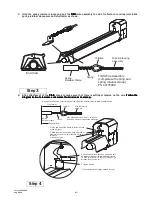

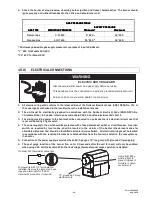

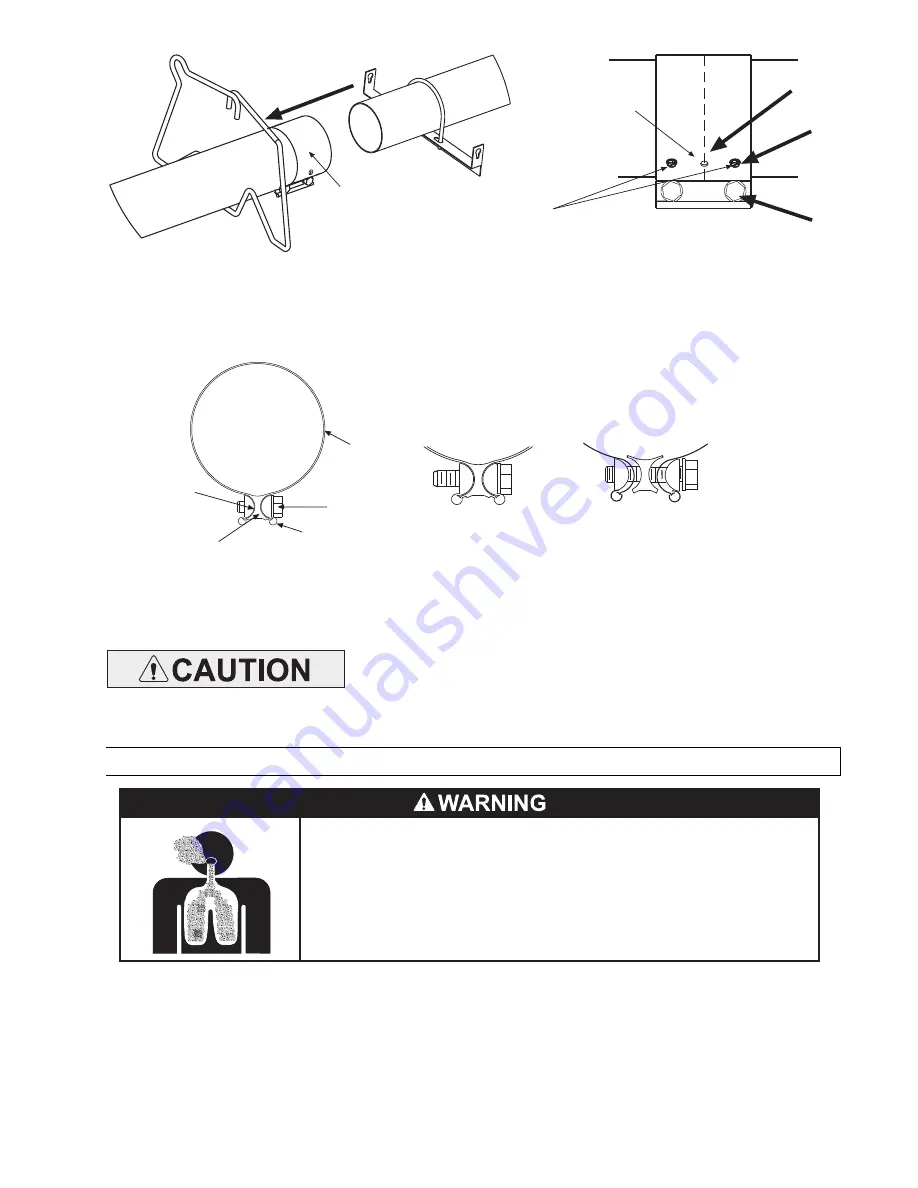

Tube

Coupling

Center both

tubes with hole

#10 Self-Drilling

Screws

(QTY 2)

4

5

7

6

4.

Slide the next tube into the coupling.

5.

Make sure both tube ends are butted together.

6.

Finish tightening both bolts to 40-60 ft.lbs. torque to ensure a complete seal.

7.

Use the two Self-drilling screws through the pre-punched holes to secure the tubes in the coupling.

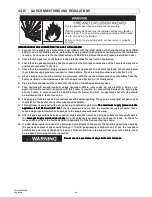

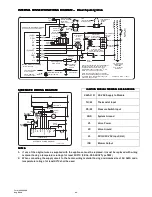

INCORRECT

INSTALLATION

CORRECT

INSTALLATION

Force

Bars

Reaction

Block

Interference

Pins

Bolt

Band

8.

Check to ensure that the hardware is completely closed and the band is seated on the reaction block and

interference pins as illustrated above.

9.

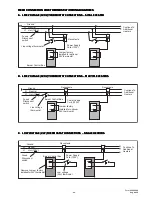

Once all the heater body sections are attached, make sure that the heater system is level. If it is not, slight

adjustments can be made using the turnbuckles. (See Section 9.0))

Important:

Important:

Important:

Important: NEVER

NEVER

NEVER

NEVER reuse a coupling

reuse a coupling

reuse a coupling

reuse a coupling.... Always install a new coupling only

Always install a new coupling only

Always install a new coupling only

Always install a new coupling only and

and

and

and

torque as per instructions above and the diagrams above.

torque as per instructions above and the diagrams above.

torque as per instructions above and the diagrams above.

torque as per instructions above and the diagrams above.

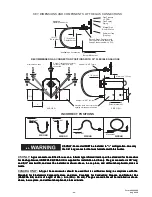

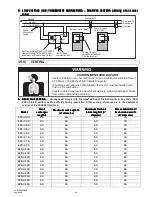

10.2)

INSERTING TURBULATORS

Failure to do so may result in death, serious injury, property damage or illness

from Carbon Monoxide poisoning.

The heater must be assembled with the correct number of turbulator sections

and tube length for the rated heat input.

The turbulator must be installed in the last tube section as shown.

POISONOUS GAS AND SOOT HAZARD

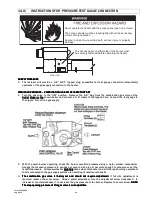

1.

Assemble the turbulators together by interlocking the slotted end portions. Slide these into the last tube

section until they are flush with the tube end. Note: Refer to the table below for quantities of turbulators

required for each heater model.