Form 43343320

-46-

Aug 2012

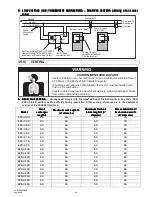

Purge the gas supply

lines.

Is the LED on the

ignition module

steady on?

Replace ignition

module.

Remove and re-insert

electrode. If it still

sp

arks to the side.

Replace electrode.

No

Y

es

Check nameplate are

the gas type, orifice

and airplates correct

for the st

ated burner

specification?

Carefully bend the

terminal away from

the burner casting.

Rest

art

troubleshooting.

No

Y

es

Check the manifold

gas pressure during

st

art up. Is it zero

inches w

.c?

No

Y

es

Has all the air been

purged from the gas

supply lines?

Check the inlet

pressure to the gas

valve. Is it between

the minimum and

maximum for the gas

pressure?

Y

es

No

Af

ter an initial step

opening is the

manifold gas pressure

correct?

Adjust manifold gas

pressure.

No

Y

es

Is there are sp

ark to

the side of the burner

cup?

No

Y

es

Check electrode

sp

ark gap. Is it 1/8?

T

roubleshooting

continued from

previous p

age

Y

es

Replace gas valve.

Remove blockage.

Rest

art

troubleshooting.

Adjust manifold

pressure. Rest

art

troubleshooting.

No

Y

es

Remove burner and

check the orifice. Is it

clean and free from

blockage?

Adjust sp

ark gap

carefully

. Rest

art

troubleshooting.

Y

es

No

Remove sp

ark

electrode and

inspect, is the

ceramic cracked or

loose?

Replace electrode.

Y

es

No

T

urn of

f gas and

check for sp

ark. Is

there a sp

ark to the

throat of the burner

cup?

No

Y

es

Are the terminals tight

on the electrode and

the ignition module?

T

ighten terminals.

Rest

art

troubleshooting.

No

Y

es

Check the terminal at

the electrode does it

arc to the burner

casting?

Replace flame sense

wire ignition cable. If

problems persist

cont

act factory for

assist

ance.

No

No

Y

es

Cont

act factory for

assist

ance.

Cont

act factory for

assist

ance.