10

Operation & Maintenance Manual

Cyclo® HBB

Cyclo® HBB

Installation onto Driven Shaft

Using Taper-Grip® Bushing

8

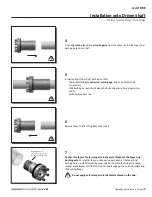

Unscrew Taper-Grip® bushing Cyclo ® HBB leaving

approximately 1 mm gap

between the bushing flange and thrust collar

9

Externally support the Cyclo® HBB before inserting the driven shaft into the bushing

Maintain external support

until all bushing socket head cap screws are tightened

to the appropriate operational torque (Step 12)

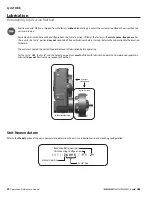

Do not apply grease, oil, or anti-seize paste to the driven shaft or

the bushing bore

before placing the unit onto driven shaft Use of these

friction-minimizing products will adversely affect the ability of the unit to

transmit torque

10

Mount the Cyclo® HBB onto the driven shaft

Do not rock or pry the unit

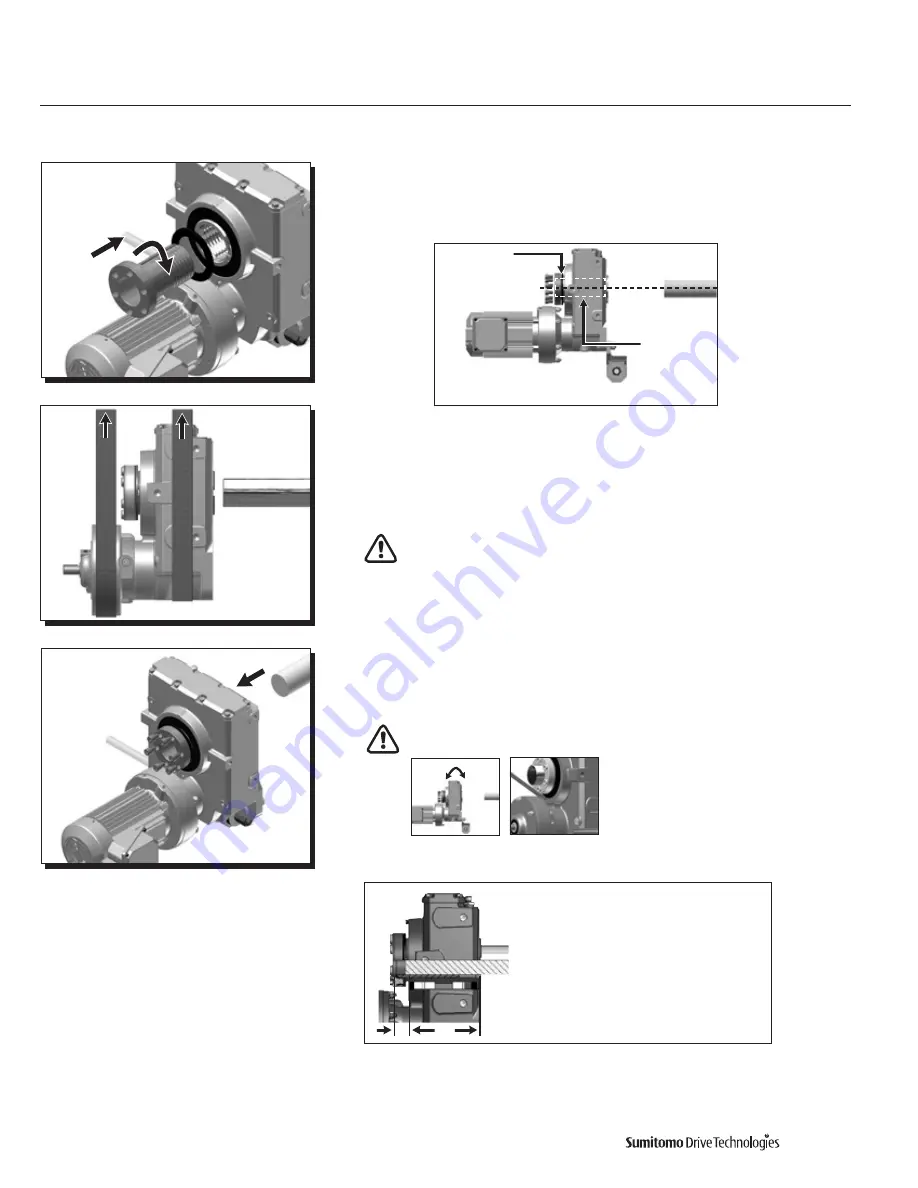

Table 1 Minimum Shaft Engagement

Leave 1 mm gap

between bushing

flange and thrust

collar

Flush

The shaft should

be flush to the

bushing flange

Be sure that

bushing and shaft

are aligned,

and Cyclo HBB

weight is supported

Align

Cyclo

Min Shaft

Max Depth

HBB Size Engagement

to Shaft End

TT (in.)

TS ( in.)

Z

4 47

1 22

A

5 00

1 38

B

5 67

1 77

C

7 36

1 57

D

8 07

1 97

E

8 86

2 01

TS

TT

Содержание Cyclo HBB

Страница 1: ...0 7 6 0 1 6 0 0 0 3 H B B O M2 0 1 8...

Страница 27: ...MA X MI N...