Página 9 de 19

CONTROL PANEL SULZER APC 1/2B

USER GUIDE

Rev.13 (2018/08/30)

3.

OPERATION

The work of any Sulzer Pumps Wastewater Spain control panel pursues the best pump pit station

operation and reliability with lowest energy and maintenance costs. Other designs aspects pursue

avoid labour and equipment accidents, not allowing manual operation if the operator

doesn’t keep in

front of the panel, allowing the complete disconnection of the control panel from outside, etc.

3.1.

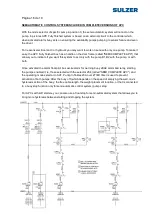

AUTOMATIC SEQUENCES

A standard APC control panel works, by default, as follow.

The main task is the pumps operation related to levels. We can set a couple of start-stop normal levels

for each pumps (or floats in case of operation with them). When the APC works with floats, the start

and stop levels are tied to the place where the floats switch on and off; when works with level sensor,

those levels can be set from the controller display (or in remote).

There is as an APC control panel option, to upgrade control and protections for an auxiliary device

related to the pit like a mixer, drain pump, valve, or a cleaner system.

The

PC 242 user and installation guides and the document named “SETTINGS IN CONTROL PANEL

MODEL APC2B COMPLETE PROGRAMMED FOR USING WITH LEVEL FLOATS” specific for this

project, show in detail how

PC 242 controls and monitors pumps and pump pit in an advanced

way

. Summarizing we can say that:

-

With normal operation, when the first start level is reached (or in case of first start float activation)

first puma will start, when second start level is reached (or in case of second start float activation)

second pump will start. We can set different stop levels, but if we set same stop level for all pumps

(or working with floats, because can only connect one common stop level float to the unit), they will

stop with a delay between stops. See

PC 242 user guide and the document named “SETTINGS IN

CONTROL PANEL MODEL APC2B COMPLETE PROGRAMMED FOR USING WITH LEVEL

FLOATS” specific for this project, for more details or to learn how to change related settings.

-

Both starts and stops are done with a

delay in between

to avoid more than two or more pumps

were started (or stopped) at the same time if max number of pumps allowed to run is set over 1.

This way we avoid electric troubles (high current loads on pump starting) and water-hammer. If you

deactivate alternation and set max number of pumps allowed to run to 1, PC 242 will allow you to

set the priority of the pump that must run to the pump with the highest start level.

-

APC can work both with level floats as analogue level sensors. Analogue level sensor allows

taking advantage of the PC242 advanced pump controller). We recommend to use a submersible

hydrostatic level sensor like ABS MD125, MD126, MD127 and HSC2, with a stainless steel

enclosure and a ceramic sensor element, instead of less robust devices or non-intrusive sensors

(like ultrasonic measuring devices) to avoid condensation, bounce signals on walls, foam effect,

etc. things that cause measurement errors and problems in the own sensor; at the same time

allowing an easier and cheaper maintenance, great robustness and reliability, etc. Pneumatic

analogue level sensors like ABS MD124 are cheap, giving some of the advantages of a

submersible sensor with the drawback that only must be used when were not supposed any risk of

the air pipe clogging.

After high level float activation system warns with the proper alarm and a semi-automatic control way of

run pumps is activated too, starting pumps available at that moment till this float deactivation. This

signal will even acknowledge all alarms not acknowledged in the controller, unblocking pumps that

could be blocked due false alarms.