Página 5 de 19

CONTROL PANEL SULZER APC 1/2B

USER GUIDE

Rev.13 (2018/08/30)

2.5.

INSTALLATION RECOMMENDATIONS

To make easier the job each terminal clamp for pump cable is named equal than the correspondent

pump cable, and the other cables are named considering their function. Due that:

1. As it is shown in the power connection page of the electrical diagram, you have to connect

main cables in clock sequence in terminals R, S, T and PE (neutral pole is not necessary).

2. As it is shown in the power connection page of the electrical diagram, Pump 1 power

cables named as U1, V1, W1 and PE have to be connected in terminal clamps B1:U1,

B1:V1, B1:W1 and PE. Pump 2 power cables named as U1, V1, W1 y PE have to be

connected in terminal clamps B2:U1, B2:V1, B2:W1 and PE. If starting method were delta-

star, we will add U2, V2 y W2 to those indications.

In case you had to connect a motor wired for delta-star starting method in a control panel

where the way to run the pump were DOL, soft starters or VFDs, you would be able to

make the delta connection over the control panel power terminal clamps connecting cables

U1 and W2 in terminal clamp U1, cables V1 and U2 in terminal clamp V1, and cables W1

and V2 in terminal clamp W1 (of course PE cable to PE terminal clamp).

3. Same way you could see that thermal signal cables from pumps (named F0 and F1) must

be connected in terminal clamps Bn:F0 and Bn:F1; and leakage signal cables from pumps

(named DI and PE) must be connected in terminal clamps Bn:DI and Bn:PE. Some small

pumps have power and signal wires in the same cable, in that case you will not have a PE

cable for power and other for signals; nothing will happen if you remember to connect

properly the PE power cable to the PE power terminal clamp, and connect the signal

terminal clamp B1:PE to one of the control panel earth connections.

In case of pump

without bimetallic thermal sensor you should remind to make a direct connection

between terminal clamps Bn:F0 and Bn:F1for this signal, if you do not do it pump

will never run.

Read and follow the measurement device user guide before to install it and connect it to the

control panel,

mainly regarding safety recommendations and indications about a proper installation.

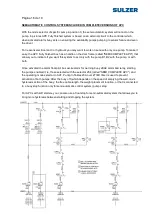

There are pump pits that have an

inlet where connect a pneumatic

sensor.

Some

kind

of

pre-

fabricated sumps made by ABS

have a T racor installed to use with

this kind of sensors and an air

compressor.

As is shown in the right side

picture, when connecting the air

pipe included in the scope of the

APC control panel with MD 124

pneumatic sensor, replace this T

racor and connect directly the

racor included in the supply (only

when less than 10 m pipe).